Decorating a house with a block house, work stages and material features

From whatever building material the building is erected, it is necessary to qualitatively carry out its internal and external decoration. To do this, today there is a huge selection of finishes, but the most acceptable and environmentally friendly, this is finishing with a block house at home.

The content of the article

Characteristics of a block house and its types

Block house reminds a log and today is very popular, both in internal, and external furnish.

Material production is made from:

- Wood.

- Metal sheet.

For reference. Metal sheets are most often used for exterior finishes, so the material is characterized by excellent technical properties.

Let's consider in more detail features:

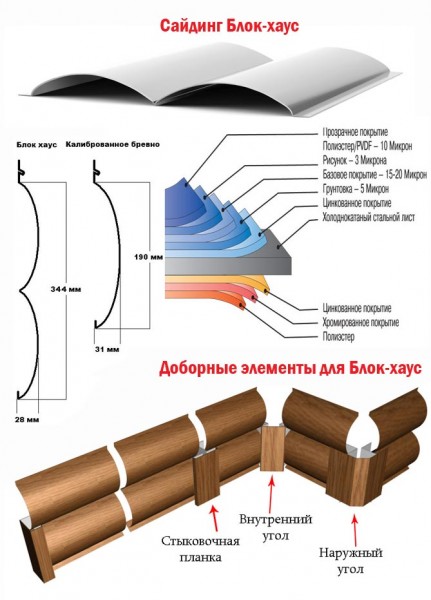

- This type of block house is one of the types of metal-plastic finishing material. It is made of zinc coated steel with a minimum thickness of 0.5 mm.

- In appearance, it is a metal plate that is internally treated with special primers and paint, and a pattern with imitation of the structure of wood is applied on top of its surface and after that it is coated with special protective agents.

- The main advantage is strength and durability. It is able to withstand temperature changes and does not absorb moisture.

He also calmly tolerates changes in weather and climatic conditions and does not deform and does not change its original appearance under the influence of sunlight. Its installation is quite simple and easy.

The whole process is similar to mounting on a siding or plastic surface.

It is made in two versions:

- In one log.

- In two logs.

Such a finishing material does not absorb a variety of contaminants and is quite easy to clean.

Wooden block house: its properties and characteristics

The block house is currently a modern finishing material. It is made of deciduous and coniferous trees, see photo.

There is a certain instruction, according to which a block house is made from:

- Cedar.

- Ate.

- Pines.

- Siberian larch and so on.

For reference. Such materials are very resistant to the process of decay, which means that they will serve as a finish for a long period of time.

Manufacturing technology:

- Finished logs are cut using special equipment using the “square in a circle” method. As a result of this process, four blanks of finishing material are obtained.

- After that, such blanks are placed in drying chambers.

- The time for which the process takes up to 14 days. When using natural drying, the process can take up to 6 months.

Tip. In finishing works, it is best to use a block house, which was obtained as a result of natural drying, as moisture from the wood gradually came out without harming the appearance of the material.

- After that, the material is subject to special treatment from insects and other harmful effects. Also with their help increases the strength of the material and the period of the operational period.

What does this material look like:

- On the one hand, it has a flat surface, which is used in the installation of a block house, and on the other hand, a semicircular one, which is the front part of the finishing material.

- In its appearance, the block house is very similar to a rounded bar.

- It is worth noting that the price of a block house is quite high. All this for the reason that the material is made from environmentally friendly raw materials - wood.

- Very often, a block house is used for exterior decoration of country houses or cottages, while it looks very beautiful.

The main advantageous characteristics of a block house made of wood:

- First of all, I want to note its strength, the surface is able to withstand significant mechanical and physical stresses and does not lose its original appearance.

- In case of damage to any element of the finish, it is very easy to replace the element or repair it by grinding. Do not forget that the decoration of the block with the house of a residential building is original and practical.

- This material has a small weight, and it is for this reason that reinforcing meshes that will help increase the strength of the finish will not need to be mounted on the wall surface.

- Installation of a block house is very simple and can be done on any surface.

- Since the material is environmentally friendly, the walls of the house will breathe and provide a favorable microclimate in the house. Block house is not only facade decoration, but also warming.

Tip. For a long service life of a block house in the decoration of a building, it is necessary to constantly look after it. To do this, if necessary, its surface should be cleaned and varnished.

The material has wide and narrow stripes. For exterior decoration, a wide block house is used, and narrow in most cases is used for interior decoration.

Installation of a block house

Decorating the house with a block house with your own hands is quite feasible, since the process of work is quite simple. Initially, it is necessary to insulate and warm the walls of the building.

Warming process and insulation

Insulation and insulation work is carried out using:

- Styrofoam.

- Polyurethane foam.

- Mineral wool.

- Hard mineral rocks.

Tip.

For the wooden walls of the house, it is necessary to make a high-quality vapor barrier to ensure the exit of moisture to the outside (the wood under the finishing material will not be saturated with moisture). As for other building material, for example, brick, such work can not be carried out.

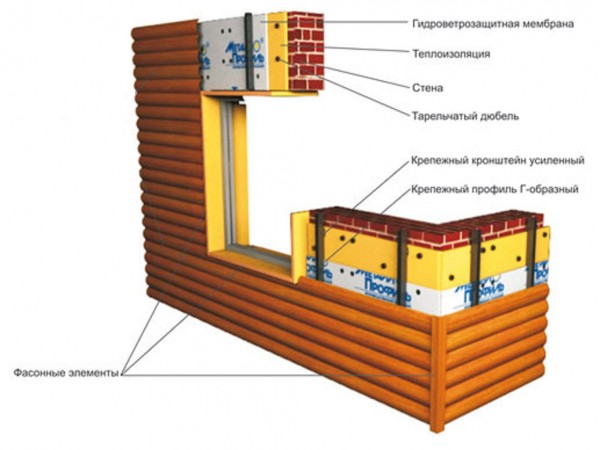

Warming and insulation are carried out during the installation of the block house on the surface.

Blockhouse exterior

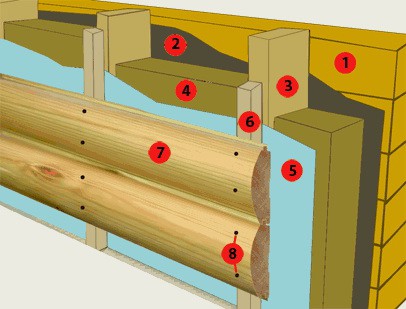

As mentioned earlier, it is necessary to initially conduct insulation and insulation on the surface of the walls. Since the block house is mounted on a vertical crate, it must first be made.

For this you need:

- Wooden bars and sticks.

- Wood screws.

- Screwdriver.

- Level.

Stages of installation work:

- The lath is mounted directly on the wall. Each element is checked according to the level, since the quality of the finish will depend on this.

- The cell size should be at least 50 cm. Only in this way can a durable fastening of the finishing material be ensured.

Tip.

If during the finishing work it is planned to carry out insulation, then the size of the wooden bars should correspond to the width of the insulation material. For example, if the width of the bar is 5 cm, then the insulation should be no more than 5 cm.

- Sheets of insulation or insulation material of the appropriate size are inserted into the cells and secured with building glue.

Tip. In order not to use it, you can cut out clear dimensions of the insulation, which will be closely placed in the cells.

- The next step will be to ensure ventilation of the block house. To do this, another crate is already being constructed on the existing crate with insulation material.

- Only in this process can smaller bars be used.All elements are mounted using wood screws and a screwdriver. The level may not be used.

Further, the installation of the finishing material itself is already being carried out.

For this you need:

- Wood screws.

- Screwdriver.

- Level.

- Sealant.

- Saw or jigsaw.

So:

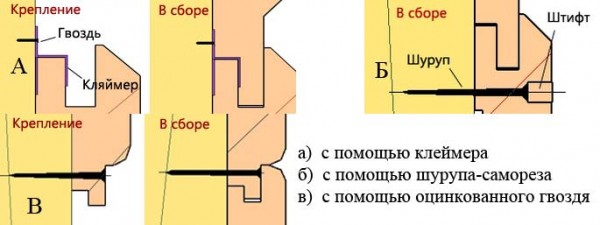

- Since there are special locks at the end of the block house panels that help fasten the material together, the main fastening is at the top of the panel. You can mount a block house both horizontally and vertically.

- The first strip of material is mounted strictly on level. It is she who will set the direction for subsequent elements.

Used with self-tapping screws with large legs. The required size is adjusted using a saw or jigsaw.

Tip. For maximum time savings, it is best to use a jigsaw.

The lock on the block-thorn-in-block house quite firmly holds all the trim elements together. To further increase the reliability of the finish, you can use a sealant that processes the joints of the material.

As soon as the block house is already fixed to the surface, you can mount decorative elements:

- Inner corners.

- Outside corners.

- Strips for masking the end of the material.

These works will be the final stage in the exterior finishing works using a block house. To make it clear and understandable what is being done and why, you can watch a video showing the whole process of work.

Block house interior decoration

The interior decoration of the room with a block house is slightly different from the external. A wooden crate is also being built on the surface of the wall.

Tip. The process of warming can not be carried out if it was carried out in external finishing work. It is also worth considering the climate in the region. If it is cold, then it will be more rational to still make warming.

Installation:

- Finishing inside the house with a block house It is carried out in the same way as with external works, only in this process strips of material are used that are not too wide, which means that it will be easier to mount a block house.

- In the interior finishing works, the internal and external corners are also used, which are fastened after the installation of the block house.

Tip. It is not recommended to use such material in rooms with high humidity.

If the block house needs to be applied, then it is worth covering it with a layer of varnish, which will protect the surface of the material from moisture and temperature extremes.