Walls, drywall partitions: features, regulatory documentation, assembly technology

How strong and durable are the drywall walls? How good are the soundproofing qualities of such a wall?

Today we have to get acquainted with the key properties of drywall partitions, with the technology of their construction and regulatory documentation governing the construction of structures from gypsum plasterboard.

The content of the article

Regulatory requirements

Does building a wall from drywall SNiP or any other regulatory document? The rules for the construction and assembly of drywall and structures made of gypsum fiber sheet are set out in the code of rules SP 163.1325800.2014.

For the convenience of the reader, we will provide here the key points of the document.

- Use for frame assembly wood is recommended only for small amounts of repair and construction work. For racks, a bar with a section of 50x60 mm should be used, and 40x50 mm as guides;

By the way: the moisture content of the wood used to assemble the frame or lathing is limited to 12 percent. The limitation is associated with the tendency of the tree to deform during drying.

- Moisture-resistant drywall is allowed to be used in humid rooms, provided that they are protected by waterproof soil, putty or other coatings, as well as with effective exhaust ventilation;

- The cavity of the drywall partition should be filled with heat and noise insulation material - glued mineral or glass wool plates;

- Jointing should be done with putty on a gypsum binder. At the same time, the joints should be primed before puttying;

- Seams should be reinforced with fiberglass tape (serpyanka). With multilayer cladding, only the seams of the upper layer need to be reinforced;

- Under the guides should be placed sealing (damper) tape;

Hint: the tape performs two functions at once. It seals the gaps between the guide bar or profile and the capital structure, and also eliminates the transmission of acoustic waves to the main walls and ceilings.

If you are preparing surfaces for painting, wallpaper sticker or laying of tiled drywall wallspenetration treatment must precede the finish. Soil will improve the adhesion of the coating to the base.

Rating

Now let's try to evaluate GCR as a material for internal partitions. So drywall walls: good or bad?

pros

It:

- Erection speed. A simple partition can be built from GKL by one person in part-time;

- Lack of “wet” jobst, which is very handy in living quarters with completed interior decoration;

- The ability to use the cavity inside the wall frame for laying utilities (water supply, sewage, wiring, etc.) or to create niches;

- Low price against the background of traditional materials (brick, ceramic blocks, etc.).

Minuses

Now let's find out if the drywall wall has flaws.

Alas, it was not without them:

- The fastening of heavy hinged furniture requires preliminary (at the stage of frame assembly) installation of wooden mortgages. You can’t hang a cabinet or a shelf for a tool in any place, as in the case of brick walls;

- GKL strength is noticeably inferior to brick or reinforced concrete panel. Having touched the wall when carrying furniture, you are very likely to leave a deep dent in it or even break it;

To clarify: the reliability of a wall made of drywall strongly depends on the structure of the frame and the number of layers of skin. In rooms with high traffic (hallways, corridors, etc.), the skin of the frame is usually double.

- Plaster does not tolerate prolonged contact with water. If you are often flooded with neighbors - GKL is not for you;

- The soundproofing qualities of a drywall partition are lost to brick or aerated concrete walls. However, as we will find out later, this problem is completely solvable.

Technology and materials

How to build a drywall partition and what needs to be purchased for construction?

Go shopping

Here is a list of materials that will have to go to a hardware store:

| Picture | Description |

| Wall drywall. It can be ordinary (for dry rooms, with a white front surface), moisture resistant (for bathtubs, bathrooms and kitchens, it differs in the green color of the surface) and fire-resistant (red). Standard sheet width is 1200 mm, thickness is 12.5, length is 2500 or 3000 mm. The length should ideally be equal to or slightly greater than the height of the floors in your house: then you will minimize the number of additional sheets that will have to be cut in place. | |

| Rack galvanized profile (PS). Its length can be equal to 3 or 4 meters, and the width of the base of the U-shaped profile varies from 50 to 100 mm, depending on how rigid the frame should be and what communications will be laid in it. | |

| Guide profile (PN) of the same width as the rack profile. | |

| Dowel-nails for attaching guides (usually 6x60 or 8x80 mm). | |

| Self-tapping screws for metal (length 9 mm). | |

| GKL screws. With single-layer casing, their length is 25 mm. With two-layer cladding, 40 mm self-tapping screws are used to attach the second layer. | |

| Damper tape. | |

| Serpyanka - a self-adhesive fiberglass mesh with a width of 5-8 cm. | |

| Insulation - glued plates of mineral or glass wool 600 mm wide. Such a width will allow the insulation to be inserted into the gaps between the posts without a gap. | |

| Gypsum putty - universal or finish. | |

| Penetrating primer. Acrylic primer is usually used for wallpaper or tile, for painting - made on the same basis as paint. |

Tool

What tool should be prepared for the start of work:

- Level, plumb line, long ruler and marking pencil;

- Scissors for metal. They will be needed to cut the profile;

Caution: it is highly undesirable to cut a galvanized profile with an abrasive tool. Due to heating near the cut, the anti-corrosion coating burns out, and in a humid atmosphere, the profile begins to rust.

- Hammer for drilling holes in concrete or brick for fasteners for guides;

- Screwdriver for assembly and skinning of the frame;

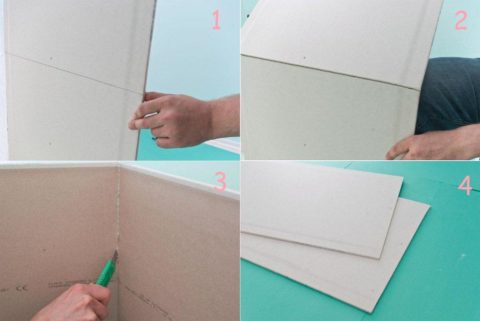

- Sharp knife for cutting gypsum plaster and jointing;

To clarify: it is more convenient to curvilinear parts to be cut out of GCR by a jigsaw. However, in this case, a lot of dust rises into the air, so the drywall is cut along straight lines and broken off along the notch.

- Capacity for mixing putty. The author uses for this purpose an empty bucket from under the emulsion;

- A pair of spatulas (narrow and wide);

- Hand grater or grinder with grinding nets.

Frame assembly

When assembling the wall frame from drywall, the technology of work should be something like this:

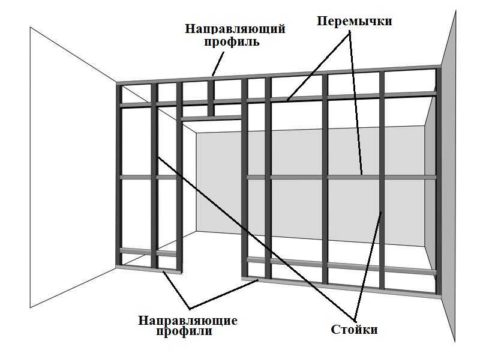

- Mark the position of the partition. Marking is carried out on the floor and transferred to the walls and ceiling using a plumb line;

- We fasten the guides according to the marking, after gluing the damper tape on the back side of the profile. Mounting step - no more than half a meter;

- We mark the position of the racks using a plumb line, making marks on the ceiling and on the floor. The distance between the centers of adjacent rack profiles must be exactly 600 mm: in this case, the edges of adjacent GKL sheets will fall on the middle of the racks;

- We cut, expose by marks and fasten with self-tapping screws on the metal of the rack. The frame is ready.

Wall cladding

The drywall sheet is placed vertically so that its edge is in the middle of the rack profile, and is attached to the frame (racks and rails) with screws with a pitch of 15-20 cm. The additional sheets are cut to size and mounted in the same way.

As always, the subtleties are important:

- The screw must be screwed no closer than 15-20 mm from the edge, otherwise it may crumble;

- The self-tapping head should be recessed by a millimeter - it has to be hidden with putty. At the same time, the hat should not fall under the top layer of the cardboard sheet sheath;

- It is very convenient to use a span to measure the fastener pitch. This is the distance between the ends of the index finger and thumb;

Reference: the span is translated into SI as 17.78 cm. Its actual size is 17-19 centimeters.

- After attaching the gypsum board to the frame, the chamfer is removed from the rectangular edges cut to the size of the additional sheets. The so-called stitching will allow you to fill the seam with putty to its entire depth;

- The insulation is installed in the frame after sheathing on one side. Glued slabs of mineral wool are cut to size with a sharp knife. At the same stage, wiring, water supply, air conditioning lines, etc. are laid in the frame.

Reinforcement, puttying, grinding

Serpyanka is glued along pre-primed seams, after which they are puttied twice. The first layer fills the seam and is applied with a narrow spatula directly through the cells of the serpyanka, the second is superimposed with a wide spatula and hides the texture of the serpyanka. Hats fasteners are putty on two times with a narrow spatula.

Do I need to putty the entire surface of drywall walls?

Only in two cases:

- If reinforced seams, due to their thickness, are visible on the wall plane. A millimeter layer of putty will make it perfectly smooth;

- If a wallpaper sticker is planned as a fine finish. The separation layer of putty will help to remove them during the next repair, without tearing the cardboard GKL shell from the gypsum core.

The putty is laid out with a narrow spatula on a wider one, and is applied with sliding movements. If you are unable to evenly apply a millimeter layer of putty - advice will help you finish the wall decoration from drywall: apply two layers of “sequential” in sequence.

After the final layer has completely dried, the GCR is sanded. It is advisable to grind in bright light (daylight or artificial): it is more difficult to miss putty defects. After grinding is completed, the wall will be dusted off and primed for finishing.

Doors

How to install a door block in a plasterboard wall?

It is attached when assembling the frame in the following order:

- When mounting the guide profiles in the lower guide, a gap remains of a width equal to the width of the door block;

- On one side of the aperture it is exposed by a plumb line, and a rack is attached to the guides;

- The door block with the installed and wedged door leaf is exposed strictly vertically, after which the rack profile is screwed to the door frame with self-tapping screws;

- On the opposite side of the opening in the same way the second rack is mounted;

- The racks are connected by a horizontal jumper screwed with screws to the crossbar of the door frame.

Reinforced frame

If you need maximum structural rigidity with minimal wall thickness from drywall - the frame assembly diagram changes somewhat: racks are made double (rack profiles are mounted side by side or nested in each other). Instead of double racks, the frame can be strengthened by investing in profiles mortgages of a 5-centimeter bar.

Special designs

Finally, we will get acquainted with several relatively exotic designs of drywall partitions, differing in strength, acoustic properties and materials used.

| Sectional view of a wall | Description | Application |

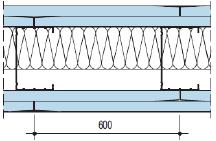

| A single frame is filled with insulation and sheathed on each side with two layers of gypsum plaster. | Hallways, corridors, other rooms with high traffic. | |

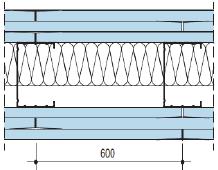

| A single frame with a three-layer sheathing fire-resistant drywall. | Fire walls. | |

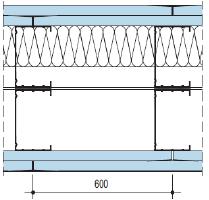

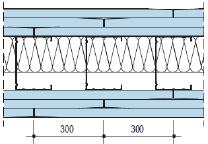

| When installing the partition, two independent frames are assembled with a minimum gap between them, providing acoustic isolation (that is, the impossibility of transmitting acoustic vibrations from one frame to another). Both frames are filled with insulation. The resulting design is sheathed with ordinary or moisture-resistant GCR in two layers. | Walls with improved sound insulation. | |

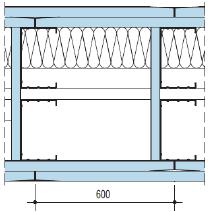

| Two independent frames are assembled with a gap between them of 3-15 centimeters. The racks of the frames are connected by jumpers. Sheathing can be double or single. | Walls with laid communications of large diameter (sewers, ventilation ducts, etc.). | |

| A single frame is assembled with a step reduced to 300 mm between the uprights. Sheathing is done in three layers, with galvanized steel laid between the layers half a millimeter thick. | Walls with protection against unauthorized entry. |

Conclusion

As you can see, the installation of partitions from GKL requires the simplest tool and is quite affordable for a beginner in construction. To learn more about how you can build drywall walls on your own, the video in this article will help you. Good luck!