Facing with granite: features and applications

The facades of most of the current structures can be decorated with a wide variety of finishing materials. It can be simple plaster, paint and other materials.

Some types of cladding have a rather long history, such as stone decoration. This is due to the fact that the material is of such a high enough quality, and the granite cladding (including the granite crumb lining) will certainly last a long operational period.

The content of the article

Granite cladding of building facades

Granite is one of the most durable types. natural stonewhile possessing a host of other benefits.

Among them, the following advantages stand out:

- Granite tiles, polishable to a mirror finish.

- A rich palette of natural shades allows you to choose exactly what is right for your home.

- High resistance to temperature changes.

- Frost, moisture, heat and sound insulation properties.

Note. It is not by chance that granite facades are very popular in almost all countries of the world. After all, if granite cladding of the facade is carried out, then it will stand for 500 years. That is, once you have invested heavily in facing granite facades, you can forget about the need for repairs.

The technology of granite arrangement of the facade of a building or some other object of the architectural ensemble (for example, facing monuments with granite) consists of several stages.

Usually, in this process, two methods of attaching a stone granite slab are used:

- Using glue (the method is called “wet”).

- Without glue - fastening by mechanical means.

Note. It is necessary to consider the suitability of the selected cement or glue to your goals.

How to clad granite facades using metal fasteners

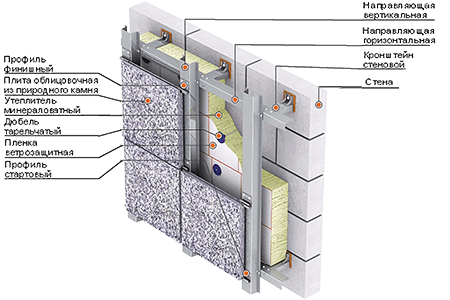

This facing option represents ventilated facade and is used for facing inclined and vertical surfaces with stone tiles, the thickness of which exceeds 10 mm.

The tile in this case can be installed in two ways:

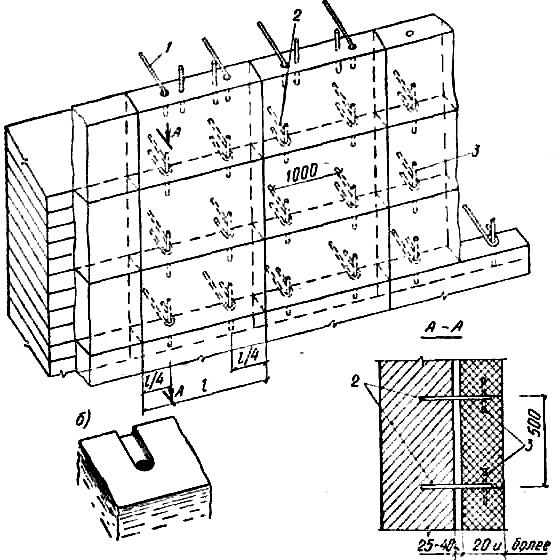

- Lining with natural granite is carried out using pre-prepared walls and simultaneous fastening with metal fasteners, meanwhile the sinuses must be filled with a cement-sand mixture.

- Moreover, very often tiles are fixed not only to the substrate, but also to each other.

- Piece, separate laying of tiles with simultaneous fastening with stainless steel wire or special mechanical fasteners.

- Wall decoration using the technology of “ventilated facade” provides for the installation on the outside of the supporting frame, on which granite facing is attached.

For reference. Between the base and the facing part, it is necessary to place a necessarily insulating material.

- As for the external decoration of large buildings, this process is very complex. Complexity outdoor decoration (regardless of whether you use artificial facing or natural granite in this case) lies in the fact that the material itself is quite heavy.

- Its specific gravity is on average 2600 kg per cubic meter, so the DIY installation process involves the presence of several craftsmen.And even in this case, this event must be treated very carefully.

For this:

- It is worth paying attention to the quality of granite tiles, since cracks (even the smallest ones) can significantly reduce the operational periods of granite material.

- Prevent water from entering microcracks, as droplets will freeze and expand when air temperature drops. Accordingly, this will expand and cracks in the granite slab.

As a result, this leads to the fact that even granite for facing monuments begins to collapse under the influence of its own weight. But the price of this material is very high in order to relate to the process of choosing granite and its further installation inattentively and carelessly.

Instructions for facing walls with granite slabs

The technology of granite wall cladding on adhesive mortar includes thorough surface preparation. For these purposes, it is cleaned of previous finishing materials, if there is serious damage, then they must be repaired and the surface of the wall is leveled.

For reference. On the brick and on the concrete wall, it is necessary to make incisions (notches) for more effective adhesion.

Installation Instructions:

- Facade cladding granite slabs made from top to bottom. By following this simple rule, you will ensure that the slabs will fit the facade much better.

- All incomplete tiles (if necessary) will be at the bottom, so they will not be noticeable. Moreover, it can easily be masked, and covered with a blind area.

- In order to cope with the process of decorating the facade with granite, you can watch several training videos. Even photo instructions for applying ordinary ceramic tiles to the walls are suitable, since this process is almost no different from what you need.

To act in this case is necessary in the following order:

- Mixing mortar for fixing granite slabs. Here you need only a special adhesive for the tile, which is designed to perform outdoor work.

If the slabs are heavy enough, then 1 part of cement and 2 parts of sand can be added to the glue. - Next, this solution is applied to the wall with a thickness of about 0.5 cm with a conventional spatula.

- This layer must be leveled with a notched trowel.

- Further, each plate should be covered with glue and using a spatula in it you need to make furrows with a width of 4 - 5 mm.

- The plate is pressed strongly against the wall, making small rotational movements so that the solution extrudes slightly.

- Depending on the model, installation is carried out either at intervals for flashing, or close.

How to fix plates on different bases

Depending on which base is on the facade, the nodes of the granite cladding can be represented in different ways.

So, for example, can be used:

- Mounting unit on the external or internal corner of the building.

- On a vertical or horizontal seam.

- Granite cladding unit on the parapet or blind area.

From granite, not ordinary plates are currently being created, but sandwich panels, whose weight is noticeably lighter than the weight of ordinary plates. Accordingly, it is much easier to do the facing work with your own hands in this case, and the price of this material is reduced due to this.

In this case, the tile is attached to a frame made of plastic and aluminum. As a result, it turns out that 1 sq.m. such a facing material is not more than 16 kg.

For reference. No matter what technology is used, wall cladding with granite slabs is always available. But first you need to carefully prepare the walls for this.

First of all, the reliability of the base is checked:

- In the event that the walls are plastered, it must be ensured that it does not peel or does not collapse. Unreliable, problem areas should be arranged and reconstructed.

- To do this, the old pieces of plaster are beaten off, and a new layer is applied to the resulting voids. Plaster can be purchased in the form of a dry mixture in a hardware store or cook yourself.

- To do this, you need to mix 1 bucket of water with 1 bucket of cement, and then add 3 more buckets of sand to the resulting mass. The plaster is applied with a spatula or trowel, and evened out with a special grout.

After these works, when the plastered surface dries, the wall must be primed, this will provide better adhesion of the plates to the wall. - If the house has just been built of brick or concrete slabs, it is necessary to withstand about six months before starting work on the facade cladding with granite. This is necessary to complete the shrinkage of the building.

Otherwise, a wall lined with granite slabs may crack. - The surface of the walls of wood is faced with granite slabs after installing a metal mesh on them and ensuring vapor barrier. For this purpose, roofing material or roofing can be used.

- If the base is represented by drywall, it is necessary to make it waterproof, so its surface is treated with a special primer. The next step is to install a metal mesh.

Thus, it is quite possible to carry out the installation of granite panels on your own, even if you have not encountered this task before. The main thing is to choose the right material and prepare the foundation of the facade.