Facing with marble and its features

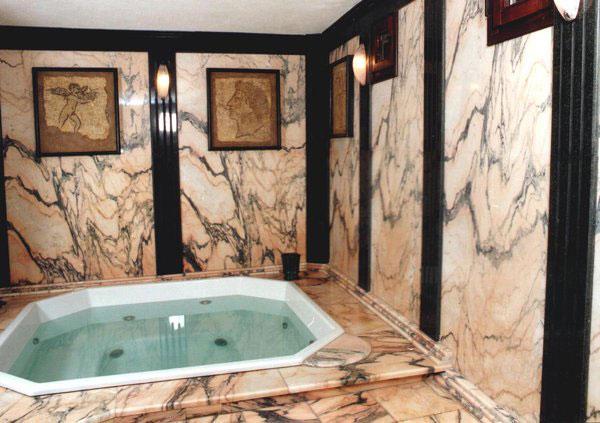

Facing with granite and marble has recently become very popular. This is due to the aesthetically attractive appearance of these materials, which help to create an elegant and luxurious design in the interior.

The content of the article

Types of marble cladding

At the moment, there are several options for facing with marble:

- Application natural stone.

- The use of artificial stone.

- Marble chips.

Each of these species has its own differences in characteristics and properties. See photos with examples of such materials in the decoration.

Natural marble in decoration

Marble cladding of natural agglomerate has differences from all other materials in that it will be environmentally friendly and unique.

Natural marble can be:

- White gray.

- White.

- Yellow.

- Gray.

- Pink.

- Red.

- Beige.

- The black.

- Brown.

- Green.

Features:

- They differ not only in the design of the color scheme of the material, but also in the quality of the surface of the marble.

- Dark shades of marble are considered the most practical, since they do not have a glossy surface and can be freely used on the floor.

As for the lighter tones, they are more used for wall cladding and various decorative elements.

Properties and advantages of marble tiles

Marble cladding is distinguished by its originality and it is not necessary to use only one shade of this material in the decoration. Using a variety of colors on the floor or on any other surface, it is possible to create quite interesting panels.

Marble itself has excellent characteristics, it:

- Durable and reliable. Due to the dense crystalline structure, marble is able to withstand quite significant physical and mechanical stresses.

- Practical, since it does not require special knowledge for the implementation of its installation.

- Moisture resistant, not able to absorb moisture and dirt.

- Fire resistant. Natural stone Does not burn under the influence of a direct source of fire.

- It does not deform under the influence of high and low temperatures.

- Frost-resistant - this ability of the material makes it possible to apply it not only in internal but also in external finishing work.

- Wear-resistant - throughout the entire period of operation, the marble lining is not able to change its appearance.

- Shockproof, breaking marble using simple physical force is quite difficult.

Marble for cladding is produced by splitting and sawing seams of crystalline rock of natural agglomerate using special equipment.

Tip. It is also worth considering that the material has a rather large mass and it is not recommended to use it on a simple surface that is not reinforced.

Facing marble thickness can be any:

- 1 cm

- 2 cm and further.

- In some cases, the thickness reaches 15 cm. It all depends on which surface the marble tile will mount.

Tip. For the floor, professionals recommend using thicker marble tiles, and for finishing the surface of the walls, the smallest in thickness so as not to create additional load on the surface.

Installation of marble tiles on the surface of walls and floors

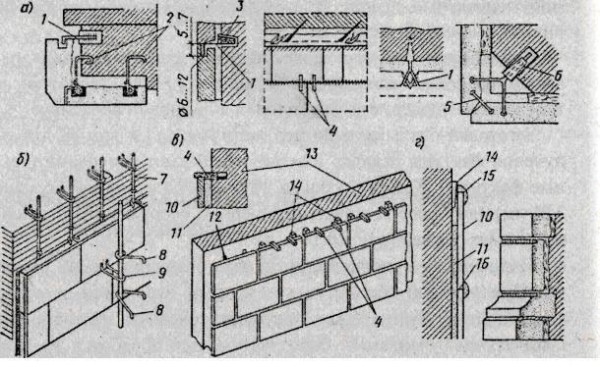

Installation technology in that and in that case is significantly different. If reinforcement is necessary on the wall when fixing the material, but such actions may not be performed on the floor.

Cladding of marble on the wall surface is carried out on the basis of the installation of ceramic tiles.

To do this, use:

- Special glue for mounting natural agglomerate or concrete mortar.

- Construction level for smoother installation.

- Tile cutter with special saws that are able to freely cut natural stone.

- Tape measure and pencil.

Tip. In most cases, it is recommended to use glue for installation on the surface of natural stone, since the strength of the concrete mortar can be adjusted independently.

Work:

- In order to get the glue of the required consistency, there is a special instruction, according to which glue powder is poured into a large volume container and only then a certain amount of liquid is added to it. The whole mass is thoroughly mixed and it is better to do this with a construction mixer at low speeds.

- On the floor, in most cases, a metal frame with a variety of mounts is used. Initially, metal profiles are installed on the surface of the subfloor.

Then tiles are mounted on them with the help of brackets. This installation method is characterized by the fact that in its process it is possible to perform surface insulation.

For this, expanded clay is used, which is poured under the lining.

Marble Artificial Stone

Artificial marble for surface lining has the main advantage - in its external characteristics it does not differ from natural agglomerate.

Although they are identical in properties, decorative marble:

- Pretty strong and reliable, but not like natural marble. He will also be able to withstand physical and mechanical stress, but not in such quantities.

Tip. For this reason, it is not recommended to use artificial marble on the floor.

- Moisture resistant, not able to absorb moisture and various liquid contaminants. The only problem will be that this type of material requires careful maintenance, as its protective layer wears out over time.

Tip. Regularly, it will be necessary to process the surface of decorative marble with a special protective agent to care for it, in order to increase the life of the material.

- Durable - the period of use of artificial marble is at least 20 years.

- Practical - has a very simple and quick installation.

- Light in weight, which makes it possible not to strengthen the surface before installation, as when using natural agglomerate.

- Wear-resistant, throughout the entire period of operation (if it is correct) does not change its appearance and loses color under the influence of direct sunlight.

- Withstands both very low and very high temperatures and the structure of the material does not deform.

- Frost-resistant, able to calmly respond to external climatic changes, which makes it possible to apply it in exterior cladding on the facade of the building.

- This is not to say that facing artificial marble is impact resistant, since by itself it mainly has a gypsum or acrylic structure. That network, in the event of a fall, there is a risk of deformation of the artificial stone or its split.

- Most importantly, the price of such material is much lower than the natural analogue of marble, which makes it even more popular.

There are artificial stones, which in their structure also have crumbs of natural marble. They are called conglomerates. Such artificial marble cladding looks quite interesting and expensive, since by external indicators it has no differences with the design of natural stone.

Installation of artificial marble

Marble cladding is no different from natural installation. Only here you can not pre-conduct work on strengthening the surface, since decorative rock It has a fairly light weight.

For work you will need:

- Concrete mortar or glue for the installation of decorative stone.

- Building level.

- Tile cutter for cutting material.

- Spatula for applying mortar.

- Decorative putty if necessary (it is used if the stone lies at a certain distance from each other).

Tip. The solution or glue should not be applied in large quantities, as unevenness on the surface from its excess can occur.

Solution:

- Independently, the solution is prepared from sand, water and cement.

- The proportions for this have long been established: 3 buckets of sand go for 1 bucket of cement.

- But to give greater strength to the concrete solution, the proportions can be changed, that is, less sand is used.

The video shows an example of mounting artificial marble-like stone on a surface using an improvised tool.

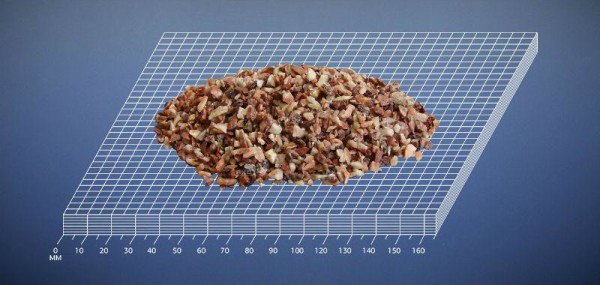

Marble chips in the finishing work

Facing with marble chips is becoming more and more popular every day. This is due to the simple and quick installation of such a tool.

What is it like? This is a loose powder, which is made on the basis of an adhesive solution with the addition of crumbs of natural agglomerate.

So:

- Marble chips for cladding has a wide range of shades.

- It is difficult to find a uniform surface design using such an original tool.

- With its help, original surfaces are created and it is not necessary to use only one type of marble chips for this.

Natural agglomerate crumbs:

- It has an attractive appearance.

- Moisture resistant.

- Practical, does not require special surface care.

- It does not absorb odors, which makes it possible to use the product for finishing the kitchen area.

- Long-life, its service life is practically unlimited.

- Wear-resistant, does not change its shade and design throughout the entire period of use of the material.

- Fire resistant.

- The lining of marble chips is able to withstand high and low temperatures, and also tolerates temperature extremes.

Installation of marble chips

Marble chips in the cladding are characterized by application only on a flat surface, since the principle of work is very similar to the use of decorative plaster.

For work you will need:

- Two spatulas of different sizes.

- Capacity for mixing marble chips.

It is best to apply the product on a plastered surface, since it will not only be even, but also provide a good bond with a solution of marble chips.