Porcelain cladding: cost estimate

When finishing any surface, it will be compulsory to draw up estimates for facing with marble, granite, porcelain stoneware and so on. They allow you to determine the exact amount of material that is required for the work.

The content of the article

Marble and its properties

Marble is an environmentally friendly decoration material. It has excellent properties and characteristics. Marble is very durable and reliable.

On its surface, it freely withstands significant physical and mechanical effects.

So:

- Marble can have various shapes and sizes. There are standard tiles with a thickness of not more than 1 cm. This type of material is used for finishing wall and ceiling surfaces.

Tip. Marble slabs that are thicker are best used for decorating floor surfaces.

- This is due to the fact that marble and all its derivatives have a large weight and it is necessary to mount it on the surface after carrying out certain preparatory work.

Marble:

- Moisture resistant and does not burn.

- Freely tolerates temperature changes.

- It is frost-resistant and does not absorb high temperatures.

- Practical and durable. Natural stone does not have a service life.

Other features:

- The main disadvantage of marble will be its price, which is considered the highest for natural agglomerate.

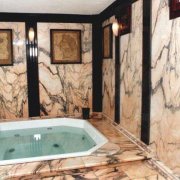

- The material has a very attractive appearance. There are a wide variety of shades. Light tones of marble are very popular.

Tip. It is best to use light marble on a wall surface, since it mainly has a porous structure, and it is susceptible to absorb dirt and moisture. It will be almost impossible to clean it.

- The surface of marble tiles may be glossy or matte. It all depends on in which region the stone was mined.

See photos with marble surface examples.

The surface of the marble can be polished or sawn, smooth or structural. All this is provided by special equipment that is used in the processing of material.

Surface mounted marble

All work is quite simple and easy to do. To do this, the surface is strengthened, since the material has a large mass.

A wire mesh is used for this, which is fastened with concrete mortar or with special fasteners.

After that, you can level the surface and is used for this:

- Stucco with additives that will increase the strength of the product.

- A solution of concrete, which is prepared from Portland cement grade 400, water and sand.

- The material itself is mounted using concrete mortar, since the weight of marble is quite large and only concrete is able to withstand it.

Tip. For an attractive appearance of cladding, marble slabs are mounted butt-to-butt. Thus, the integrity of the finish is obtained.

How to correctly calculate the required amount of marble for decoration

Marble cladding the estimate is made in advance. It helps to accurately determine the amount of material required.

For this, it is used in the calculations:

- The size of marble tiles.

- The parameters of the room or a separate structure that is being finished: height, width, length.

- Thanks to these parameters, the quadrature of the finish is calculated. All indicators are multiplied. The width, length and height of the material itself are also taken into account.

Tip. It is best to purchase material with a small margin. This will help in case of deformation of one of the finishing elements to replace it.

Porcelain tiles in decoration

A material such as porcelain tile is made of several components:

- Clays

- Special additives.

- Feldspar.

So:

- The name comes from the fact that clay is used for making ceramic tiles or other products of this type, and feldspar is a fundamental component for the formation of such a natural agglomerate as granite.

- Thanks to this composition, granite has excellent strength and reliability. It is also moisture resistant and its surface is not able to absorb dirt.

It does not burn and freely tolerates low and high temperature conditions. - The practicality and wear resistance of the material is also at a high level. Its service life is at least 25-30 years.

For all the time of use, the surface does not lose its properties and appearance.

The sizes of porcelain stoneware can correspond to the sizes of simple ceramic tiles:

- 20x30 cm.

- 30x30 cm.

- 60x30 cm.

And there may be more:

- 60x60 cm.

- 90x90 cm.

Tip. Such parameters of porcelain stoneware are applicable in the decoration of the floor surface, since due to the dimensions they are used to finish very quickly.

Facing estimates porcelain stoneware also provides for the calculation of such dimensions of the material in the calculations.

The surface of the granite can be:

- Smooth or embossed.

- Structural or rough

- Matte or glossy.

Note. It all depends on what kind of material production technology is used. On the surface there can be various imitations of finishing and building materials. Thanks to this, it is possible to create an original design of any surface.

Surface mounted porcelain stoneware

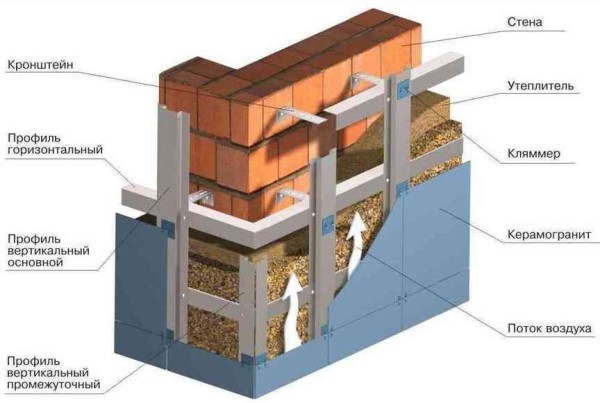

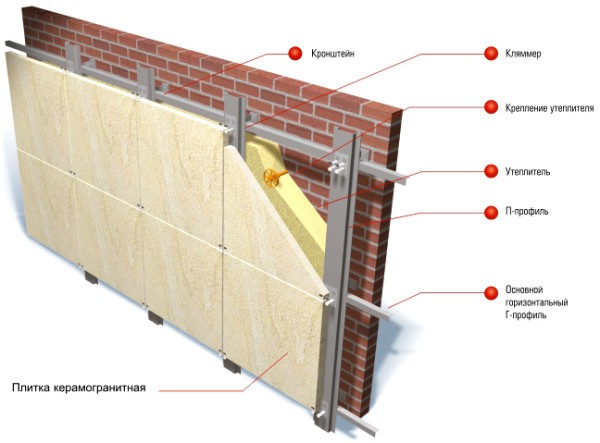

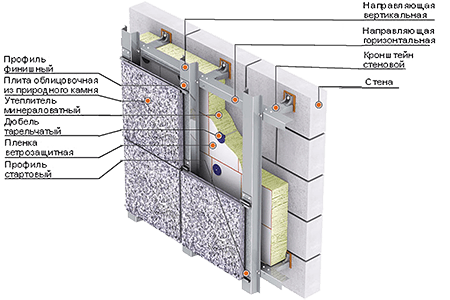

The installation of such material on the wall and floor surface has certain differences. In some cases, porcelain tiles on the floor are mounted on a special profile frame.

Work:

- Installation on a wall surface is quite simple and quick. For this, the principle of fixing simple ceramic tiles is used. The video shows this process.

- In this case, a solution of concrete or a special adhesive for ceramic tiles is used.

Tip. The glue, which is intended for the installation of ceramic tiles, must be moisture resistant and tolerate weather and climatic influences freely.

Also required:

- Cruciform beacons, since the tile should be mounted at an even distance from each other, and cruciform beacons provide it.

- Tile cutter for porcelain tile so that the material can be trimmed.

- Construction level and tape measure.

- Decorative putty, which will be needed after the installation of porcelain stoneware to mask the masonry joints.

- Sour cream porcelain stoneware should also include the consumption of auxiliary and fixed assets: glue, beacons or concrete mortar.

What needs to be considered in order to correctly compose the consumption of materials for finishing work?

Porcelain cladding estimates include:

- The dimensions of the room itself or a separate plane on which it is planned to perform the cladding.

- The parameters of the finishing material. The cash flow depends on them.

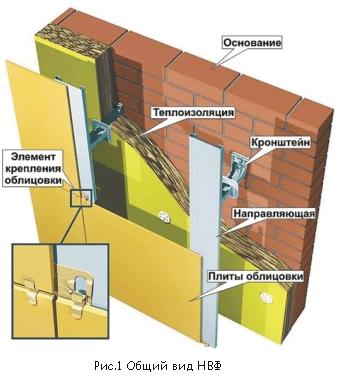

- The calculation of materials for each surface may be different. For example, the estimate for facing the facade with porcelain stoneware should have items such as insulation and insulation of the structure.

Tip. To correctly draw up an estimate for the consumption of material for decoration, it is necessary to accurately determine the quantity and quality of work,which will be performed on the surface and all materials are bought with a small margin.

It is especially important to consider this when purchasing porcelain tiles. It should be from one batch, as there may be problems with an uneven shade of the surface if the material is already coming from another batch.

Granite in surface cladding

Natural sinter has been used for exterior and interior decoration for many years. It has an attractive appearance and the whole finish looks rich.

So:

- The properties of natural stone are quite high. It is very durable and reliable.

It is not able to accept wet influences and well tolerates weather and climatic phenomena. It does not burn and is not too well processed. - Finished granite can be used in the form of tiles or small blocks of stone. It all depends on the finishing options.

The price of this and that type of granite finishing material is different, since there are different processing methods.

The surface of the material may be:

- Sawn or polished.

- Glossy or matte.

- Chipped or rough.

In order to get one or another surface, special instructions and appropriate equipment are used. The color scheme of natural granite is diverse, which makes it possible to easily select the optimal method of surface treatment.

Note. Granite can be used both on the wall and on the floor surface. The installation principle will be similar.

Installation of granite and cost estimates

Before performing the installation, it is necessary that the estimate for granite lining be ready. It takes into account the size of the surface that requires finishing.

Tip. If it is necessary to use the exterior cladding of a building with granite, then all the building parameters in general are taken into account.

The estimate for facing with granite may consist of:

- Insulation and insulation of the building (if necessary).

- The amount used for this material, taking into account their coverage (focusing on the parameters of future cladding).

- Amount of materials for installation of porcelain tile.

- Consumption of porcelain stoneware (oriented on the structural parameter and on the size of the material).

Granite has a large weight and for this reason the surface undergoes strengthening work. The installation principle is similar to fixing marble or other natural agglomerate.

To fix granite on the surface, it is best to use a concrete mortar, which, after solidification, has greater strength than glue for the same work.

No material can compare with marble or even granite! I kind of got into the idea of decorating the bathroom with marble, but when I saw the price tag for this product, I immediately changed my mind.