Tile: work steps

Any building made of modern materials requires finishing work, which is carried out both from the inside and outside. At the moment, the most popular is tiling at home.

It can be used on wall surfaces and other interior items.

The content of the article

Works in which tiles can be used for surface decoration

All works are divided into internal and external. Depending on this, a choice is made of the type of tile material, which today has a wide variety.

So:

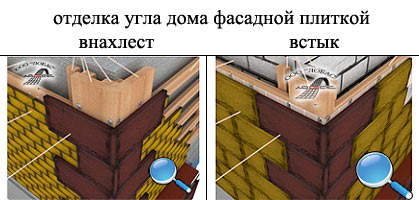

- In the process outdoor decoration Very often, insulation of the building is performed in parallel.

- But, this only if it will be carried out without much difficulty, if the finishing tile is mounted on a frame or crate.

Decorating houses with tiled tiles began to be used relatively recently.

During this time she is growing every day. All this is due to the fact that the tile is very practical and durable.

Types of tiles

At the moment, finishing plates for the house can be made of:

- Plastic.

- Pottery.

- Minerals

By their properties, some of them have similar properties and characteristics. See photos with home decoration with the above materials.

Home decoration plastic tiles

This type of material has become very popular because of its versatility, as it can be used in both exterior and interior decoration works. It has excellent technical properties and characteristics.

Plastic panels:

- Moisture resistant.

- Frost resistant.

- Wear resistant.

- Practical.

- Durable

- It has a large selection of surface finishes.

Note.

They freely withstand significant and sharp temperature changes and do not fade under the sun. All this makes it possible to maintain the original appearance of the finish for a very long time.

It is also worth considering that the price is very affordable, which makes the material even more popular.

The sizes of the plates can be different:

- 1x1.5 m.

- 1x2 m.

- 1.25x2.5 m.

- 1,50х3 m.

Thanks to these sizes, the cost of finishing material is significantly reduced. Mounted plastic panels very simple.

The surface does not require preparatory work for this, and they can be mounted on any material, since the crate is the basis for their fastening.

Installation of plastic tiles

There are two types of mounting on the surface of plastic panels:

- To the frame.

- Directly to the surface of the wall.

The latter installation method is possible on a wooden or drywall surface.

For him are used:

- Self-tapping screws with decorative hats.

- Screwdriver.

- Building level.

- Pencil and ruler.

- Scissors for metal or jigsaw.

- Roulette.

Tip. To make the process of installing plastic panels a little faster, instead of screws and a screwdriver, you can use a construction stapler with brackets of the necessary shade.

Stages:

- You can also use liquid nails or construction glue. Quite often, in this way, the kitchen is finished with tiles in order to update its appearance.

- The second method of attaching plastic tiles is used on wall decoration.Initially, on any surface, a crate is made, which can be made of wood or a metal profile.

The choice of one or another type of lathing depends on the quality of the surface itself and the weight of the finish.

Tip. If you need to make a very large surface with plastic tiles, then a metal profile frame is used, which has special strength and durability.

- Before using a wooden crate, it is worthwhile to evaluate not only the climatic conditions in the region, but also what period of time a house will be operated in a year.

- This is necessary due to the fact that wood can freely absorb moisture.

For this reason, in most cases, the wooden frame after manufacturing is painted with paint or varnish, it is quite easy to make it with your own hands.

Need for such work:

- Metal profile or wooden planks of the same diameter.

- Screws for metal or wood.

- Rotary hammer, screwdriver (can be replaced with a drill).

- Building level.

- Tape measure and pencil.

- Jigsaw or scissors for metal

- Dowels.

Installation:

- At the very beginning, with the help of dowels, horizontal or vertical strips are fixed, which will be the basis for the manufacture of the crate. All other elements are attached to them with screws.

- Once the crate is ready, you can proceed with the installation of plastic tiles. If they are large, then they are mounted using self-tapping screws with decorative hats or a construction stapler.

Each seam in the finishing process is treated with sealant for a better and more reliable finish.

Tip. During the installation of plastic tiles, it is possible to easily warm the building.

And it will be best to use solid mineral materials for this:

- Extruded polystyrene foam.

- Polyurethane foam.

- Styrofoam.

Characteristics:

- Mineral wool in most cases today is used to insulate the floor.

- Due to their strength, these materials are simply inserted into the cells of the crate and tightly fixed in them.

Facing tiles for decorating a house from plastic are mounted on the frame without making the repeated lathing, which is necessary for the installation of wooden finishing material in the case of insulation work on the walls.

Ceramic tile for decoration

Before ceramic tile used only in interior decorating. At the moment, thanks to modern technologies of its production, the exterior walls of the building can be made by it.

Also, a very part is used to finish the pipe with tiles. All this is due to its technical properties and characteristics.

Properties of ceramic tiles:

- Moisture resistance, as it is made of baked clay and coated with protective agents on top.

- Wear resistance - thanks to the protective layer, this finishing material is able to maintain its original appearance and design for a long time.

- Frost resistance, as some types of ceramic tiles can withstand very low temperatures.

- Practicality - thanks to the protective layer on the surface, the tile is not able to absorb dirt and is therefore quite easy to clean. You can use abrasive detergents for such work and not be afraid that the surface will be scratched or begin to deform.

- Durability, since you can use the material in the decoration for a long time (15-20 years). Here a large role is played by the shrinkage of the structure, which can disrupt the finish.

- Durability and reliability. Ceramic tiles able to withstand very large loads.

Note.

There is a large selection of this material, which differs not only in its size, but also in its external design. There are various shades of ceramic tiles.

Thanks to new fashion trends, terracotta tiles made of ceramic in the bathroom or kitchen area have become popular. Colors are also fashionable: lilac, pearl, turquoise and other bright shades.

Surface mounted ceramic tiles

Ceramic tiles are mounted only on a flat surface. For leveling, plaster or drywall is often used. Here everyone chooses the best option for themselves.

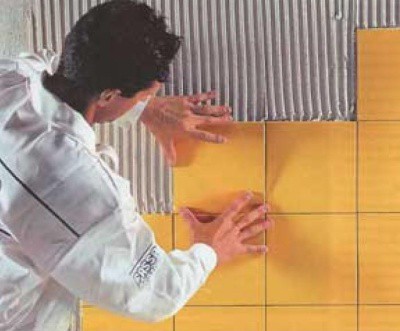

Stages:

- The use of plaster is considered a very long process, which is accompanied by a large number of works and materials used. After this, there is always a lot of construction waste.

- What can not be said about the use of gypsum board, which is very easily mounted on a metal profile frame. The whole process takes a little time and is not considered time-consuming.

To install ceramic tiles you will need:

- A solution of cement or a special glue that must be diluted with a certain amount of liquid and for this there is an instruction on its packaging. The cement mortar is prepared independently from water and cement.

- The construction level by which each tile will be exposed to the surface and only after that be fixed.

- Trowel and putty knife for applying cement or glue to the surface of the wall and to the back of ceramic tiles.

- Cross-shaped beacons that are inserted between each tile and thereby ensure an even distance between them.

Installation of ceramic tiles can be seen in the video.

Mineral plates in the decoration of premises and methods for their use

Miplite finish is possible only on a flat surface. Quite often, such material is used in finishing work on the ceiling.

The material is extruded polystyrene foam, which at this stage of development of production may have a different surface and design on it.

On the walls, the decoration of the miniplates is not often used, it has excellent properties:

- Sound and vapor barrier, which makes it possible to use this material without additional insulation and insulation work. It is because of this that very often they are called soundproofing plates for decoration.

- Simplicity of installation, since it is possible to mount the tile not only directly on the surface, but also on a kind of frame made of special profiles with walls.

- Moisture resistance, as the material is not able to absorb moisture or various impurities.

- Lightweight.

There is a type of mineral tile that has a perforated surface. With its help, a unique decoration of the room is created, since if you hide a certain number of lighting devices under its surface, you will get a play of light in the interior.