Decorative facing tile: types and features

One of the easiest ways to place emphasis in the interior, or to give expressiveness to the facade, is a decorative tile for facing. The functionality, beauty and durability of the material, for many decades only contributes to the growth of its popularity.

What are tiles made of today, by what methods are they mounted - and in general, what options can be used to decorate a house from the outside, and which ones for rooms? Our article, as well as the video presented in it as a good example, will answer many questions of our readers.

The content of the article

Universal wall cladding

If we consider that the word “decor” in Latin means “compatibility, decency,” the conclusion suggests itself: the more complex the design of the front surface of the tile, the smaller the area should be faced with it. So that the decoration does not turn out to be too pretentious, but looks “decent”, the wall cladding with decorative tiles should be harmoniously combined with simpler types of decoration.

Before talking about design, as such, let's figure out what types of tiles are used purely for facadesand which are purely interior. But we will begin our story with a universal option, which is brick tile, stylized as a brick.

Clinker Advantages

Under the term "clinker", today lies a rather large list of structural and finishing materials, which are made using the same technology, the main raw material of which is shale clay. These are brick and pavers, floor coverings and elements of stairs, decorative facing tiles for interiors and facades.

- And also, clinker thermal panels are made for cladding external walls (see Cladding facade decoration: installation features), which are a multi-layer insulated module having on the front side a layer of clinker tiles imitating brickwork. Such a finish, which you see in the photo below, can equally well be done with piece tiles and thermal panels.

- It is believed that the founders of the clinker are the Dutch, the first to produce incredibly durable material for paving the road at the beginning of the 19th century, the covering of which, by the way, is in working condition two years later. In fact, they only improved the technology that appeared long before that.

- In general, clinker is the same ceramics, it is only fired at higher temperatures. At the same time, the clay raw materials are completely sintered, in which it turns into an incredibly durable, waterproof stone. The blanks are formed both by pressing and by extrusion, which allows you to get a product of any shape - including a three-dimensional relief on the surface.

- Given all of the above, it becomes clear that a beautiful clinker cladding tile can not only decorate the walls, but also, forming a sealed coating, protect them from destruction as much as possible. Gone are the days when the facades were lined with solid clinker bricks.

- The reason for this is the rather high price of the material, and the significant weight of the brick, which requires a more powerful foundation.The tile is easy to install, it can significantly reduce the cost of decoration, and the possibilities for design, especially interior, gives incomparably more.

- Above is an example of the design of internal walls with the same brick tiles (see. Indoor brick and tile), which can be carried out both outside and inside the building. But below you see a purely interior option. This is a decorative facing tile for apartments, with a three-dimensional relief, imitating a stone cut into thin long strips.

- As you can see, clinker decorative tiles for wall cladding do not have to have a characteristic red-brown color. It has a wide range of shades, and a huge selection of textures, which allows you to implement the most interesting ideas for the design of an apartment or a private house.

This is not to say that clinker tiles are the most economical option - they are quite expensive. But if we take into account not only the service life of the coating itself, but also the durability of the walls tiled with such tiles, it becomes clear that these costs are fully justified.

And if you compare it with natural stone, then clinker tiles will be not only cheaper, but also more practical, since it does not require additional care in the form of hydrophobic impregnation.

Ceramics and Porcelain Tiles

Ceramics and clinker are very similar concepts. The main differences between these technologies are the firing temperature, the types of clay used and the raw material composition, as well as the methods of molding and glazing.

Ceramic tile more porous, and inferior to clinker in strength. That is why it is often used for interior work, where these indicators are not so important.

So:

- The cost of finished products depends on the technology option that was used in the production - and there are many of them. In fact, each manufacturer has its own secrets: clay grades, their combinations, improving additives. Suppose, with a semi-dry method of preparing raw materials, a ceramic mass clogged with foreign impurities may well be used.

- This technology includes such steps as cleaning on rollers, drying, grinding, and then wetting the mass, curing it, and molding the bars, which are then cut into tiles. Semi-dry tiles have a fairly low bending strength, and therefore are intended only for wall cladding.

Note! For manufacturers, this method is attractive in that you can use almost any kind of clay, even maloplastic. Billets are immediately sent to the oven, which gives significant time savings, and time, as you know, is also money.

- In order to produce high-quality tiles, the ceramic mass is prepared using the slip method. The clay is first crushed to obtain a specific fraction and sieved, as a result of which unnecessary inclusions are separated. To remove iron compounds from raw materials, it is subjected to electromagnetic cleaning. Then the maximum grinding of the mixture, its hydration, enrichment with the necessary additives is already carried out.

- And then, molding, drying and firing, which is the most important operation, and can be carried out in two stages. After the first firing, glaze is applied to the tile surface, or a pigment composition, which will determine the color of the finished product. Some technologies involve the application of glaze before the first firing, which reduces their shrinkage.

We can talk a lot about ceramic tile manufacturing technologies. Even more there is a technique for its design. But today another name is also heard - porcelain stoneware (see Porcelain cladding: finish features)How is it different from traditional ceramic tiles? We will discuss this later.

Distinctive features of porcelain tile

In principle, many people know about porcelain stoneware, but most associate it with facade cladding mounted on a frame, as well as with stairs and floor coverings. But not everyone knows that there are also decorative tiles for facing the facade with glue, as well as the most chic design options for interiors, which can also be made of porcelain.

So:

- In appearance, it is no different from ceramics, since the difference lies again in the production technology. The raw materials here are natural, but their composition is more complicated. There are two main stages: pressing and firing, after which face cutting (rectification) is already performed, surface polishing, etc.

- There is only one sign by which you can visually distinguish porcelain from ceramics. If you carefully look at the end of the tile, it is easy to see a clear border between the colorless “body” and the colored face layer. Porcelain stoneware does not have such a separation, since it is stained throughout the mass.

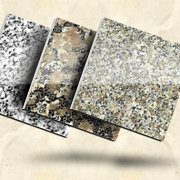

- The tile is a monolithic homogeneous product, on the edges of which a characteristic crystalline luster is visible, which is very similar to a slice of natural granite. If we talk about physical and mechanical parameters, then porcelain stoneware is closer to clinker than to ceramics.

- Suffice it to say that on a ten-point hardness scale, the highest level of which belongs to diamond, porcelain stoneware is assigned a hardness of at least seven points. So this material will give a hundred points ahead even to its prototype - natural granite, on which, by the way, cracks and chips may appear over time. And at the same time, mind you, the price of porcelain stoneware is much lower, which, undoubtedly, is a weighty argument in its favor.

- Porcelain stoneware tiles are classified according to the type of front surface. It can be, like ceramic, glazed, can be polished or matte. There is also the so-called polished or semi-matt type, with a pleasant to the touch, silky surface. It is obtained due to partial polishing, in which the top layer of the material is not completely removed.

As for the size range and the external design of ceramic granite tiles, its range is in no way inferior to ceramic tiles. There are large-format panels for the facade, installed on the crate, and medium-sized tiles for facades, pools and bathrooms. There are also products with a format of only 5 * 5 cm, with which you can lay out beautiful panels in the form of mosaics, one of which you see in the example above.

Artificial stone and tile

The beauty of natural stone never left mankind indifferent, and only the high cost at all times prevented its widespread use as a building or finishing material. But since there is a demand, there will always be a proposal, and people have long figured out how to create an artificial stone that looks and looks like a natural stone in appearance and characteristics.

So:

- For its manufacture, mainly mining wastes are used. The crumb of stone, bonded with polyester resins, allows you to get a complete imitation of certain breeds. Interestingly, such a composite acquires the properties characteristic of polymers. That is, a stone made artificially does not absorb moisture - and this is a very valuable quality when it comes to finishing the socles and exterior walls of houses.

- Decorative stone, successfully used today for facade cladding, is also made from colored concrete and a sand-and-sand mixture, which is either molded or semi-dry pressed. Moreover, the stone is molded, can be made directly on the construction site, which greatly facilitates the process of transportation, sorting and selection of products in the composition.

- Polymerized tiles and decorative stone are made from ready-made dry mixes, which are sold in all construction stores. It is enough to dilute the composition with water, as the instructions on the package say, and it can be poured into forms. By the way, they can also be bought, and on sale you can see a good assortment.

Advice! In an extreme case, the compounds - this is what silicone molds are called for, can be made independently by pouring liquid natural silicone into several natural stones laid in a metal or plastic box. Who is interested in this topic, the materials you can easily find on the Internet.

- If composite stone is used mainly for exterior work, then for interior decoration, it is possible to make gypsum tiles, which are molded in the same way, but at a cost that is not an example cheaper. Looking at a sample of interior design in which we see an imitation of brickwork made of gypsum tile, we think you will understand that this is a good choice.

- Whoever does not want to engage in self-production can just buy gypsum tile. By the way, there are not only options for mounting on glue on sale, but also tiles that are fixed to the crate by means of screws or special fixing strips.

- And in conclusion, we turn your attention to the tiles and bricks, which it is already impossible to make with your own hands. The production technology is based on semi-dry pressing, therefore, finished products are called hyper-pressed. They include sand, limestone, dyes, and a small amount of cement.

- As a filler, manufacturers can also use tuff, shell rock, pumice, slag - that is, all kinds of stone waste. This allows you to reduce the cost of production, which, however, does not affect its quality.

As a result of pressing, high-strength products are obtained, which are similar in this indicator to porcelain stoneware, and give a hundred points ahead to clay and silicate bricks. Since this material is facade, it only imitates the texture of brick and stone. As for the color scheme, it is wide enough to satisfy any customer needs.