Facing tiles in the interior: characteristics and installation

At the moment, there are no restrictions on the use of one or another finishing material in the design of the building. But, despite this, wall tiles for the interior are in great demand.

The content of the article

Varieties of ceramic tiles for decoration

Facing tiles for interiors can have not only a surface with a different design, but also several types, which in their properties and technical characteristics have a certain similarity, but different in cost.

There are a large number of types of ceramic tiles:

- Plain clinker tiles.

- Majolica.

- Cotto.

- Terraglia.

- Gres - granite.

Note. Although all of these types use clay dough to make the material, various technologies for their production are used.

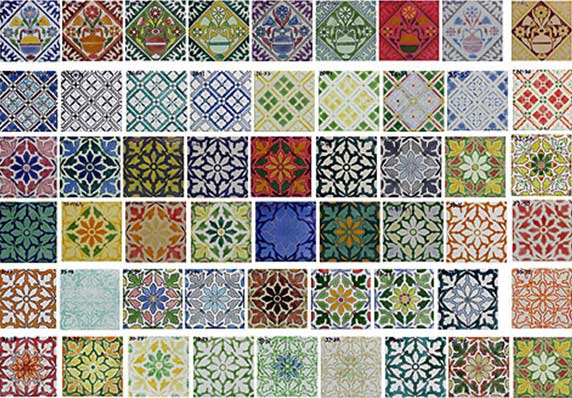

The photo shows examples of each tile.

Plain ceramic tile (clinker)

Interiors with tiles of this type are quite diverse, as well as the range of its application. It can be single-fired or double-fired.

That is, two types of clay are pressed under the influence of high temperature and are then subjected to single or double firing.

So:

- The tile has a wide variety of sizes, ranging from ordinary mosaics, the size of which starts from 10x10 mm, and ending with fairly large elements, from the size can reach 90x90 cm.

- Last option ceramic tiles It is mainly double-fired, as it is used mainly for decorating the floor surface or for exterior finishing work.

Majolica - ceramic tiles

This type of ceramic tile differs from the previous one only in its upper layer. It is also made of clay, which is pressed under the influence of high temperature and only then burned twice.

After that, an opaque layer of glaze is applied to it.

It can also have any sizes and designs, it is used mainly in the same place where ceramic tiles can generally be used:

- Kitchen area.

- Bathroom.

- The bathroom.

- Entrance hall and other premises.

- The price for it is slightly higher than for the simple appearance of ceramics.

Note. At the moment, you can find a variety of imitations of masonry, stone and other surface treatments. You can even apply various patterns and ornaments using special equipment.

Ceramic tile Cotto

- Cotto tiles are made from special types of clay. It undergoes double firing.

Only unlike the previous one, it does not have a glazed protective layer. For this reason, the surface of this type of ceramic tile can only be matte. - The range of its application is not limited to the wall surface. Most often it is used in floor finishes.

For reference. Cotto has a wide variety of surface finishes. There are also imitations of various finishing materials, which makes it possible to create unique interiors.

Terralia ceramic tile

This ceramic tile differs from all in that it is made from valuable clay. There are also sand and flux in the composition. The tile has high strength due to double firing.

As a rule, the tile after manufacturing is white. After manufacturing, it is possible to apply any pattern to the surface.

Then you can already apply a small layer of glaze to the surface to fix the design, the interiors lined with Terralia tiles look very interesting.

Ceramic Granite - Gres

- Porcelain tile (seePorcelain cladding: laying technology) differs from other varieties of ceramic tiles in its strength and structure. It is made using two types of clay dough, which is pressed twice under the influence of high temperatures and twice amenable to firing.

- This tile also has a wide variety of surface finishes. It can be matte or glossy.

Tip. This type of tile, due to its structure and its density, is best used for decorating the surface of the floor or for exterior decorating.

The advantages of ceramic tiles and its properties

The main advantage of such a popular finishing material is its practicality. The surface of the ceramic tile due to the protective layer that is applied during its manufacture does not wear and does not undergo deformation under significant mechanical and physical stresses.

The properties of ceramics include:

- Moisture resistance, which makes it possible to use it to design a room with high humidity.

- The ability to withstand very high temperatures and not be deformed.

- Frost resistance - since clay itself can freely withstand low temperature conditions, the material that is made from it and subjected to various processing has the same characteristics.

- Wear resistance - despite the long term of operation, the external design of ceramic tiles does not change. But this largely depends on the quality of the material itself and on behalf of the manufacturer.

As a rule, all of them give a guarantee for their products. - Durability - you can use the finish made with ceramic tiles for 20-25 years.

- Impact resistance does not apply to all types of ceramic tiles, but only to those that are fired twice.

Note.

In addition, it has a very easy installation, but such work can only be done on a flat surface. This is due to the fact that the back side of the tile is flat, respectively, it requires a similar characteristic from the surface on which the installation will be performed.

Where can I use ceramic tiles in the decoration

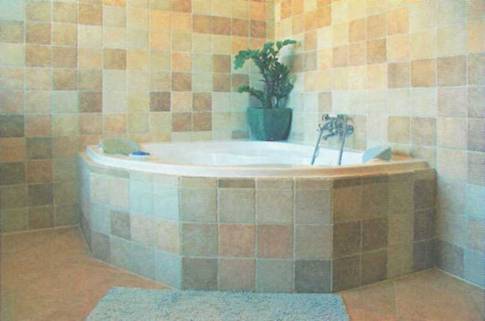

As mentioned earlier, the range of application of ceramic tiles is so wide that there are no restrictions for the stylistic design of the room. The interiors of wall cladding with ceramic tiles are diverse and it is not necessary to use only this type of material for decorating surfaces.

Ceramic tiles look very good in combination with:

- Stucco.

- Paint.

- Decorative stone

- Wallpaper and so on.

Other features:

- Most often you can find material in the decoration of the bathroom or in the general sanitary zone. The use of ceramics is not limited only to residential premises.

There are also certain requirements for the design of the kitchen area of a cafe or other eating places. - Also very often used ceramic tiles in the hallway. She draws the entrance area and mainly on the floor.

Tip. Since the ceramic tile has a high fire resistance threshold and can withstand the high temperature freely, it will be possible to make the floors warm in the room, since the ceramic also has excellent thermal conductivity.

Ceramic tiles are also used in exterior works for finishing the basement or corners of the structure. Porcelain stoneware is used here, which has excellent properties and technical indicators.

Installation of ceramic tiles

All installation work on any type of ceramic tile is very simple and it is possible not to use the services of a master in this area, but to do it yourself. Only initially will it be necessary to prepare a surface for this.

There are two types of mounting material:

- Floor.

- Wall.

Attention.

Preparatory work on these surfaces is not too different from each other. If the ceramic tile is mounted on the floor, the floor is pre-aligned with a screed.

It is carried out using a concrete solution, which can be prepared independently from:

- Water.

- Sand.

- Cement.

So:

- It is best to knead the solution in a special container with a construction mixer to give the composition a homogeneous mass.

- You can also use the finished composition of the liquid floor, which in a short time quickly levels the surface with pre-installed beacons.

If the installation is carried out on the wall, then there are also two options for leveling the surface:

- The use of plaster.

- Drywall Applications.

Tip. If there is a desire to very quickly and efficiently, and most importantly - without much clogging the room, level the surface, then it is best to use drywall.

What you need to provide:

- This material is mounted on the frame from special profiles. This frame is already attached to the wall surface with dowels and screws.

The joints of the drywall sheets are processed with putty and, after drying, are sandpaper. - As for the use of plaster, this process can take up to a week and thereby increase the period of finishing work. In the course of such actions, “Start” plaster is used, which is initially applied to the surface.

The number of its layers depends on the size of the defects on the surface, but each of these layers must be processed with sandpaper. - Then “Finish” plaster is applied, which is able to hide the defects of the initial application. It is also treated with sandpaper.

Both of these products are sold in bulk form, and to make them a complete solution there is an instruction according to which a certain amount of liquid is added to a container with powder.

Tip. For a greater bond with the mortar, with which ceramic tiles will be mounted, the surface must be primed with a special tool.

For installation you will need:

- Cement mortar or tile adhesive.

- Construction level for smooth installation of the material.

- Tape measure to determine the exact size of the distance and the tile itself.

- Cross shaped beacons whose function is to ensure an even distance between each ceramic tile on the surface.

- Small trowel or trowel for applying mortar.

- Decorative putty for masking joints of tiles.

On the video you can see the whole process of installing ceramic tiles.