Material for plastering walls: what will be required for work

Materials for wall plaster very different can be used. Plastering is a traditional method that allows you to align the walls of buildings being built and prepare them for finishing, which must be done outside the building and indoors.

To avoid errors during the process, you need to choose the right material for plastering the rooms. And how to do this, the article will tell.

The content of the article

Features of plaster mortars

The basis of any plaster mortar is:

- Astringent component, which may include:

- cement;

- clay;

- lime;

- gypsum.

The type of component is influenced by the nature of the intended work and the place where they will be carried out:

- outside the building;

- indoors (see Types of plasters for interior decoration: choose correctly).

- Aggregate. When plastering walls, it is traditionally sand. If aggregate is not added to the cementitious elements of the mixture, the plaster will be unstable, and the surface treated with it will become covered with cracks.

Plaster mortar can be:

- Clay (see Clay stucco: where to use). It is used quite rarely for interior and exterior decoration of buildings. The solution has a low level of strength, which sharply limits its scope.

The composition is diluted to obtain a homogeneous mixture. To get better plaster, other components are sure to be added, such as:

- gypsum;

- cement.

When using clay in its pure form, it is more likely that the plaster will simply crack in dry and hot weather.

- Clay-calcareousconsisting of:

- liquid clay dough - one part;

- lime - 0.3 - 0.4 parts;

- dry sand from 3 to 6 parts, added if necessary, so that the solution acquires the necessary fat content for wall coating.

- Lime-gypsum. In this case, in order to increase the setting speed and increase the strength, gypsum is added to the lime or clay solution, which allows the mixture to begin to set in about 5 minutes. To prepare it you need:

- pour gypsum into the water slowly, constantly stirring;

- mix the composition quickly until a homogeneous liquid dough is obtained:

- the resulting gypsum dough is added to the prepared lime mortar;

- everything is quickly mixed again.

The whole process must be completed in no more than two minutes. Usually 3 servings of lime mortar are taken and one gypsum is added to it.

Tip: The solution should be prepared in small portions, which will be used in 3-5 minutes.

- Clay Gypsum. In the composition of:

- one piece of clay dough;

- three to five parts of dry sand;

- 0.25 parts of white gypsum.

Prepare the mixture, as well as the lime-gypsum composition.

- Clay cement. It can be prepared in the same way, but as part of the solution:

- one piece of clay dough;

- three to five parts of dry sand;

- from 0.15 to 0.2 parts of cement.

- Cement (see Cement plaster: do it right). Cement grade 400 or lower is used in this solution. From 1.5 to 5 parts of sand is added to the cement, depending on the surface for applying the material. Preparation of plaster is quite simple:

- sand is poured into the container:

- cement is added, it is better to use a sufficiently large funnel for this;

- the dry mixture is thoroughly mixed;

- water is added gradually. In this case, the mixture should not be too liquid.Otherwise, there will be practically no adhesion to the surface being trimmed.

The solution should be thick enough so that the mixture is applied easily, and well kept on the surface. Do not make it too thick. In this case, adhesion to the wall surface will be poor.

Insufficient amount of concrete milk in the plaster will lead to shedding.

Tip: A cement mortar made in a ratio of 1: 2 or 1: 3 will become better stuck to the surfaces, and then it is easier to plaster the walls.

- Cement-lime. In the composition of the solution:

- lime dough;

- sand;

- cement.

Such a composition is easily applied to any surface and firmly adheres to it. To prepare the solution you need:

- mix cement with sand and get a cement dry mixture;

- prepare lime dough with a thick sour cream consistency;

- the resulting mixtures are combined together;

- thoroughly mixed.

To get high-quality plastering of the walls, materials are of great importance, but it is also advisable to use convenient construction equipment.

It can be:

- Plastering machines.

- Aggregates.

At the same time, the quality of applying the plaster and the performance of the work will be significantly higher than when doing the whole process with your own hands.

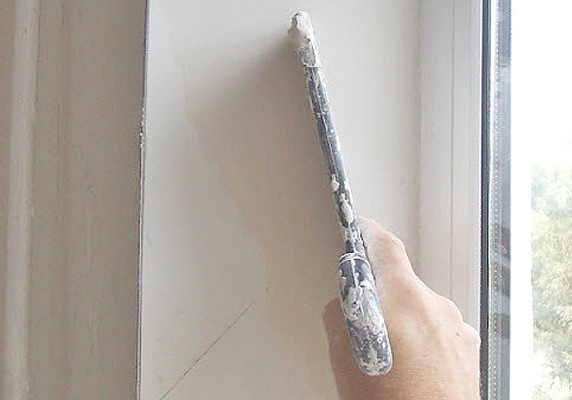

How to plaster slopes

Before finishing windows, it is necessary to choose the material for plastering the slopes (see How is plastering slopes).

This is the most popular and oldest finish.

To complete the process, you can take:

- A solution consisting of cement and sand (see Cement-sand plaster: material features).

- Dry formulations based on gypsum. The price of these materials is less than sand and cement mortars.

After applying any type of plaster, puttying of the slopes is carried out, then painting them or wallpapering them.

The instruction indicates that the slopes should be putty strictly after the final drying of the plaster layer:

- Cement plaster usually after 10 days.

- On the basis of gypsum - after three days.

The period of complete drying depends on the ambient temperature. In any case, you need to wait for the mixture to completely dry, otherwise the wet coating layer will peel off after applying the paint.

Tip: When finishing surfaces, at all stages you need to ensure that there are no drafts, all windows should be closed.

How to texture interior using vray

Vray decorative plaster materials are created by 3D 3D modeling using a computer.

The main advantages of using 3D panels are:

- Original appearance that have v-ray plaster materials and their modern design.

- A large selection of different samples of textures and images, which perfectly illustrates the photo.

- It is easy to choose the required shape of the panel to any interior of the room.

- If necessary, the decorative plate can be repainted, and even apply the technology of gilding or patination.

- 3D panels are made only using the latest technologies and from materials that are environmentally friendly.

- The panels are fireproof, do not absorb odors and are well protected from minor mechanical damage.

How to make vray material, decorative plaster for him and its features will show the video in this article.