Base lining: making the right choice

Facing the basement of buildings is a rather important point in the decoration of the entire building. Facing the base is not only for beauty, but this finish is also of practical importance.

In this article, we will consider how to properly cover the base with stone or other material. We will understand what is faced with the base.

You can also watch photos and videos on this topic and make the right choice.

The content of the article

Base trim features

The facing base is made for a reason, it also performs certain functions. And it’s absolutely the same if you use it for decoration artificial stone for facing the basement, or use for facing the basement granite.

The price here does not matter. Functionality is important.

So:

- Knots base trim must be well protected. The finish carries a protective function and protects the foundation from moisture. The humidity in the room depends on this in many respects.

- Protects the base from destruction, that is, it affects the durability of the entire structure. The microclimate in the room also depends on this;

- Stands for facing the plinth, or any other material will smooth out ambient temperature differences. This is a particularly topical issue in the offseason;

- When performing facing, you can always carry out additional insulation of the foundation. For this, it is worth choosing the right material.

After all, stones for facing the basement can only do this job minimally. And such a design can significantly reduce energy costs.

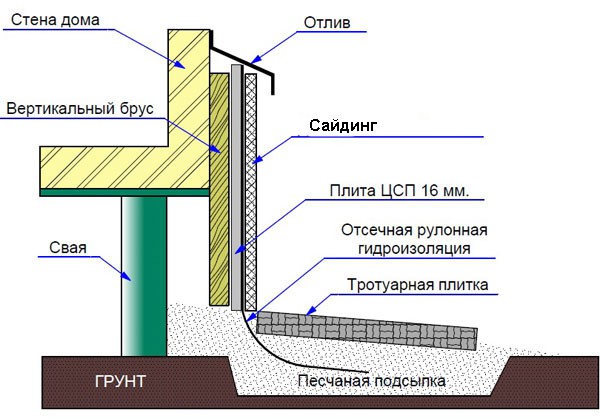

Attention: Before facing the base, you should also worry about the blind area. Without providing a quality installation, you run the risk of simply nullifying the effect of finishing.

Surface preparation

The base lining units will fully perform their functions only if they are attached to a well-prepared surface.

What you should pay attention to when doing this work:

- First of all, it is necessary to qualitatively prepare the surface. It will be great if you completely remove the old coating.

Do not forget to apply a primer layer, give preference to deep penetration liquid; - Correctly define the line for the start of the cladding. To do this, when applying the marking, the hydraulic level should be used.

It is with his help that this work can be performed most qualitatively; - When doing the crate, use a gauge. By eye, this work is not performed.

Use a square and a building level. Keep the crate in the same plane. To do this, diagonally strapping should pull the fishing line; - Before installing the insulation, a layer of waterproofing should be applied. It should be put in the joint. It is necessary to do an overlap of the order of 10 cm.

When fastening to the elements of the crate, it is necessary to make a twist of the material and only after that carry out the fastening;

Attention: When fastening, never use the wall plugs from the sets. They will not provide reliable mounting. To do this, you need to purchase plastic in a disagreement and separately buy screws. They must be taken a couple of mm more from the cross section of the plastic hole.

Choose material

The blind area and decoration are done in the complex. Here it is necessary to choose the right material to get the maximum effect.

Installation instructions for almost any material are on our website, but it still needs to be selected correctly.If there is a liquid base under the stone and without insulation, then the effect will also be minimal.

But if in this option you apply the frame method with the use of insulation, then this will be noticeable. If the base is made with high quality, insulation was used, then decorative finishing can be done.

Brick tile

The peculiarity of clinker tiles is that the wall lined with it differs little in appearance from a brick wall. And the advantages, in comparison with a real brick, are mass.

So:

- She is light and thin. Only 8-21 mm thick, and the surface dimensions are 21-21 × 5-7 centimeters;

- In addition to flat tiles, you can always find on sale corner versions of clinker tiles, which will greatly facilitate the work on wall decoration;

Attention: Usually, clinker tiles are used for finishing the base, therefore, before proceeding with installation, it is necessary to note the height of the base. Having determined the level, you can proceed to gluing the tiles.

- As glue use a frost-resistant adhesive mixture. It is applied to the inner surface of the tile, as well as to the wall itself. This method provides reliable bonding;

- After the mixture is applied to the surface, it is necessary to glue the material within half an hour, otherwise the mixture will harden and lose its quality;

- A couple of days after the end of work, the joints between the plates must also be covered with the same glue. There is no need to process the clinker tiles with any water-repellent means, since the material almost does not absorb moisture.

Stone tile

How to clad the base natural stone we’ll take a look now. A basement made of stone tiles looks very effective, although its cost is not small.

So:

- Typically, such tiles are made of sandstone or limestone, but you can find basement tiles made of more expensive materials - marble or granite;

- The sizes of such tiles can be different: from small, like ordinary brick, to huge, the height of the entire basement;

- Tiles can have any texture. Its surface can be absolutely flat (polished or polished) or granular;

- The material is mounted on the wall using the same technologies as clinker tiles. A special solution applied to the surface of the wall and tiles, it is glued to the building;

- When finishing with this material, it should be borne in mind that the elements can be of different thicknesses. So them and fasten in a discord.

This will give a natural finish. Just select the parts for installation, the longer ones are used longer and the volume goes upward.

So simply you will ensure the stability of the elements during masonry.

Caution: Do not use other adhesive materials that are not intended for external surfaces. This will cause cracks and destruction of the stone tiles.

Sand Tile Polymer

A new type of finishing material can be considered polymer sand tiles. It is decorated with the external walls of buildings, especially such decoration is suitable for socles.

So:

- This durable composite building material imitates brickwork with relief or creates the illusion of a “ragged” wild stone;

- Tiles made of polymer sandstone are good because they have a small weight, which makes it possible to clad even those walls that can not withstand heavy loads;

- Another advantage of polymer sand tiles is that it is sufficiently plastic and does not undergo chips, it is rarely possible to see cracks on it;

- It is also very moisture resistant, tolerates wet weather. The polymer is mounted sand tiles to the outer walls with the help of special screws to the wall itself, or to its crate;

- It is easy to care for such a base, it is not afraid of low temperatures or a thaw, and for the wall cladding you can put additional insulation.

Resin Based Tile

Tile based on resin is an imitation of clinker brick or sandstone:

- The thickness of such tiles is 3 millimeters. Due to the easy flexibility of these tiles, they can be tiled even very complex walls, for example, semicircular;

- In addition, the tile can be bent at the corners of the walls, cut to the required size with scissors;

- Tile resin-based tiles on any surface: plaster, concrete, insulation material;

- The material is available in a fairly wide range: 9 different colors, the surface is smooth or corrugated. The size of the tiles is 24x36 centimeters;

- Glue is applied to the inner surface of the tile with a special notched trowel. Pokleyka starts from the corner, and at the same time four tiles must be glued at once;

- After the tiles are glued, there is no need to fill the seams. Simply spread the glue with a damp brush. Within two to three days after the end of work, the wall must be protected from moisture.

Fake diamond

Decorative lining of the basement with artificial stone is quite common in everyday life. The base made of artificial stone is no different from the base made of natural stone.

This is essentially the same wild stone, only made artificially.

So:

- The artificial stone in its composition has such chemical and organic additives that provide the stone with resistance to severe frosts. Externally, the material looks natural due to the dye;

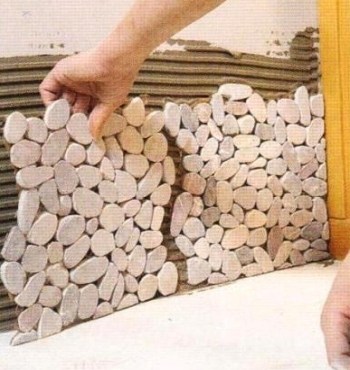

- An artificial stone can imitate a "ragged" stone, river or rock. Moreover, any of them can be made in a different form - regular or shapeless;

- Its dimensions are 7-23x15-31 centimeter. Artificial stone tiles are mounted thanks to an elastic or simple adhesive solution;

- After mounting the tiles, the joints are usually filled with a special solution for narrow joints. It is possible to extend the service life of a basement made of such a stone by several years: by protecting it with a hydrophobizing solution.

PVC panels

If there is no purpose to trim the basement of the building with tiles or cover it with plaster, then you can use PVC panels. This material has already fully entered our lives and is popular.

So:

- They are quite light, convenient and quickly mounted, they are not capricious to the weather;

- PVC panels can imitate brick or mosaic;

- Panels are mounted on the crate (metal or wooden). But first, the level of the base is determined, and then the lower side of the profile is fixed, the relative of which the first panel is fixed;

Attention: if you decide to use wood as a frame, then do not forget to do the treatment with an antiseptic, which is on sale. This material will significantly increase the life of the entire structure. Only processing is done in advance, the slats still have to completely dry.

- When performing this type base trim It is crucial to make the frame right. The final geometric shape completely depends on its implementation;

- When calculating, you should correctly calculate the height of the crate. One point is important here, the insulation should not be deformed by panels, otherwise it will lose its properties.

Make a couple ventilation clearance. And then everything will be fine; - Be sure to install waterproofing. This will reduce the intake of moist air. Each base lining assembly must be reliably protected;

- This work can be completely done with your own hands and this attracts the consumer, this will significantly reduce the cost of the final cost of the work;

- Each such panel has ridges and grooves with which it fits into another such panel;

- The base is usually covered with a special overhead profile;

- The brick imitation cladding may have a plinth top and not a patch profile;

- The corners of the walls are closed with corner fragments. It is not necessary to treat the base additionally with any hydrophobizing compositions.

Mosaic plaster

Mosaic plaster consists of very small grains - from 0.8 to 3 millimeters. This finish imitates a multi-colored mosaic, and thanks to the resin, which acts as a binder, it is waterproof, but vapor permeable.

So:

- Mosaic plaster perfectly tolerates severe frosts, is not subject to mechanical damage. But these properties are decisive when choosing a material for finishing the base;

- Mosaic plaster lies on almost any surface: concrete, gypsum, lime-sand or cement plaster.

Caution: There are limitations to consider. Mosaic plaster should not be applied to heat-saving or calcareous plaster materials.

- Mosaic plaster is applied manually using a special stainless steel grater. You can pre-apply a lining mass to the wall, which will improve adhesion.

The material is applied in a thick layer, then the grater is distributed in one direction over the surface. In order to avoid the appearance of joints, the “wet to wet” method should be followed.

Now it’s clear that we cover the base only with material that will fully perform the functions that are described above. Even when using the Bassoon brick, this is worth sticking to.

Even lining with slate this must be considered. The most important thing is not to rush and carefully weigh everything and provide for it.