Finishing the foundation with your own hands, taking into account its design features

Different types of foundations suggest some differences in the implementation of their finishing decor: finishing a pile foundation is not at all like facing the surface of a strip structure. In this article, we will try to cover both options and tell you what materials are used in a particular situation, or have universal application.

You will also be offered a video on the topic: "Finishing the foundation with basement siding with your own hands."

The content of the article

Foundation Walls: Cladding

The foundation part of the building is in direct contact with the ground and, first of all, needs protection from moisture. The aesthetics of the façade also, of course, matter, but of secondary importance.

The best way to finish the base should be considered the option that can meet both the one and the other requirements, as well as be simple for self-fulfillment.

- The strip type of foundation is the most common and differs from other structures by the presence of solid walls, the ground part of which is called a base. This is what you need to protect to the maximum - especially when you consider that in the vast majority of buildings with a strip foundation there are basement and semi-basement rooms.

The variant of their internal arrangement is not so important: whether there is a technical floor or, for example, a living room with a fireplace, the basement walls should not only be airtight, but also warm. You need to choose the appropriate finish option, and our instructions will help you with this.

Adhesive finishes

Concrete or brick foundation walls are an ideal base for adhesive cladding. Despite the fact that the laboriousness of works on facing with natural stone (see Facing the base with natural stone: types of material and installation steps), as, however, the price of the material is quite high, its popularity only increases over time.

So:

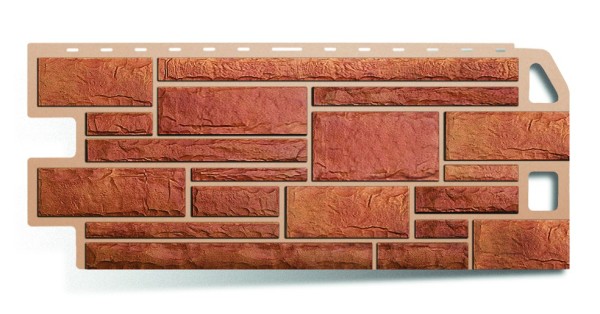

- Finishing with a foundation stone gives the simplest and most unpresentable facade a solidity and a solid appearance - hence the people's love for its textures. For the same reason, and even due to its lower cost, ordinary plastic panels stylized as stone are also in demand.

- But we will talk about imitations a bit later, but for now we’ll talk about natural material. For cladding with glue, stones with various cutting variations, but not in too large a format, are used. For large plates, due to their solid weight, the installation technology is somewhat different, for them it is necessary to produce anchor fasteners.

- They are not used in low-rise construction - these are options for administrative and public buildings, architectural monuments, etc. Due to the lower price and the possibility of manufacturing directly on the construction site, decorative analogues are often used instead of natural stone.

- Of course, they are inferior to natural stone in terms of aesthetics of the front surface, but they have much less weight, which significantly reduces the load on the foundation. Dry mixes are on sale, as well as silicone molds, compounds specifically designed for the manufacture of decorative stones.

- And here is the paradox: the stone is called artificial, and the components in its composition are natural - cement, gypsum, sand, stone chips. You will find instructions for its manufacture without problems. But as for the installation technology, the origin of the stone does not affect it in any way.

- The second most popular material used for facing the basement is rightly considered a brick tile under a brick. Unlike real brick cladding, it does not require support on the foundation, reinforcement and anchoring - all that has to be done when finishing the basement with brick.

- By the way, if you use paving stones for cladding, that is, a stone having the shape of a solid brick, the masonry will also need support. Therefore, preferences are usually given to such stone cutting options as: noodles; combined rectangles or triangles; various mixes.

- Of particular interest to house owners is a torn stone, popularly called a casing - you see it in the photo below, as well as the exact size - usually in the form of brick tiles. Naturally, when using products of different configurations, some adjustments are made to the installation process.

- Facing of stones having an irregular geometric shape: buta, pebbles, wild and torn stone is folded like a mosaic. Each detail is first selected in shape and color, in accordance with them it is laid out and numbered - and only then mounted on the wall.

- A stone with precise geometric shapes is glued according to the same principle as ceramic tiles (see. Tiling the basement: make a choice) Here, for proportion, it is important to observe the thickness of horizontal and vertical seams, therefore, during installation, they use wedges or crosses.

Otherwise, there is no difference in the sticker methods. The main thing is to qualitatively prepare the surface and use the right glue - it is better than factory manufacturing.

The adhesive method of facing the foundation is used only in two cases: if the basement is insulated from the inside, or when there is no need for it at all.

Some Siding Information

If the foundation walls require insulation: external or even double-sided, there is only one way out: use materials mounted on the crate. There are many types of them, but specifically for foundations, various types of siding panels are used, as well as thermal panels, which differ only in structure.

- In appearance, they are very similar, and therefore we will not focus on thermal panels. In low-rise construction, compact modular panels with imitation of textures of natural materials are in the lead today. It is about finishing the foundations and walls of small private houses. Facing large office centers and other administrative buildings is usually part of the project.

- It's not so simple: if, for example, a stone or porcelain stoneware facing of a foundation is designed, then in the form of slabs mounted on a frame. And under the weight of this cladding, the calculation of the supporting structures is performed. Although, with the advent of modern lightweight materials, heavy types of cladding fade into the background.

Today, in the designed buildings, the championship is behind panels of sheet metal, especially durable HPL plastic, as well as sheet materials made of composite aluminum. Siding is practically not used for finishing the foundations and walls of multi-storey buildings, since the strength of the material does not correspond to the loads.

And the cost of facing with large areas of the facades is quite high.

Types of panels

As already mentioned, in private construction basement siding breaks all records of popularity. These are panels specially adapted in size for convenient finishing of the foundation (see Facing the foundation with siding and other materials).

On average, the height of the base is 700-900 mm.The height of the panels varies between 450-695 mm, which allows you to block the foundation with a whole module or make two rows.

So:

- You can, of course, cut off the pieces, but this will violate the integrity of the picture and you need to try to choose a panel size that would do without cutting. The length of the modules usually does not exceed 1.25m. The front surface of the basement siding, as a rule, has the texture of stone, brickwork, tile or wood chips.

- The exception is keramosiding, which offers a wider range of textures. Imitations of wood, decorative plasters, and even photographic images are added to all of these options. But it, if it’s already used, is for the complete decoration of the facade, and not just for the basement. And the fastening system of ceramic siding, due to its more substantial weight, is somewhat different.

- Ceramosiding is the most expensive type of panels, and, as a rule, imported. In a more affordable option for the manufacture of siding using: polymers, metal, cement, composite wood. Vinyl and polypropylene panels are leading the way by a wide margin. What to do: the lower cost of the material is always the determining criterion for its choice by the buyer.

- Moreover, polymer options have a very decent appearance. This type of panels differs from the long-length familiar to all only in the shape and stylization of the front surface, which is oriented to the foundation of the facade. Regarding the structure of the panel: it, by analogy with the front siding, also has a form factor located between the castle and nail strips.

During the installation process, a similar set of accessories is used - with the exception of the connecting strips, which in this case are not needed at all.

Since the panel imitates masonry with offset joints, the joint is zigzag and it is almost invisible on the surface. The seams at the final stage are simply sealed with sealant.

Design Opportunities

As for the installation technology, there are only minor differences when installing the crate, associated with the configuration of the cladding panels. In general, with the advent of siding in the basement version, it became possible to significantly diversify the facade cladding and even think about its design.

- Modular panels are just as successfully used for full wall cladding, as well as combined with vertical or horizontal siding. By the way, long-lengths are also used for finishing the basement, but only if it is flush with the surface of the walls, and the walls are clad from the ground.

- This is exactly the kind of option we see in the example above, where, by the way, the basement siding is sheathed not with a foundation, but with pediments. In general, siding panels can be combined as you like: in texture, color, shape and even the direction of the lining.

Therefore, they rarely when sheathing only the foundation, and finish the house completely. The main thing here is not to buy material spontaneously.

First, it is desirable to sketch the facade; think about which architectural elements it is better to focus on; choose shades of panels that are not only in harmony with each other, but also combine well in color with the roof.

Stilt House: Secrets of Finishing the Basement

The fact that the panels are installed on the subsystem allows us to use them not only for insulation and finishing of the walls of the strip foundation, but also for installing a false base on the facades of buildings erected on columnar and pile foundations (see. Facing the pile foundation: false basement) In fact, there is simply no other such convenient and inexpensive method as finishing the pile-screw foundation with basement panels.

- If on a concrete wall under them it is necessary to install frame racks, then metal piles themselves play the role of load-bearing elements of the crate. For the convenience of fastening the panels, they are tied around the perimeter with a beam or PPN profile. How it looks, you can see in the picture below.

- In addition to the horizontal belts of the lathing, vertical elements are also mounted: corner and additional racks between the piles, allowing the panels to rest on the entire area. Otherwise, the finish of the pile foundation is no different from the sheathing of an insulated tape base: first, corner elements are mounted, then the starting profile along the lower perimeter, and finally the panels themselves.

- When one row of panels is enough to cover the height of the base, then the locking part of the module is latched into the groove of the starting bar. Its upper edge through the mounting holes is fixed to the crate at the corners and, depending on the length of the panel, in one or two places in the middle.

- If finishing above the base is done with another type of siding or with a completely different material, the top of the cladding will be covered with a base tint. If siding sheathing is carried out along the entire wall: from the bottom to the top, then the tide can be arranged along the bottom line of the cladding. It is necessary so that condensation does not accumulate under the lining.

- It would be unfair not to mention another option for finishing the basement of the house on stilts. These are walls in half a brick, which are erected around the perimeter of the foundation. They can be faced with stone or immediately laid out of decorative bricks.

- Previously, this was, in fact, the only way to finish the foundation of this type. It is quite time-consuming and expensive, because under the wall you need to pour a shallow foundation foundation. In addition, you have to wait for concrete to gain strength, in general - a whole story.

- Materials such as flat slate or profiled sheets do not at all look like a basement cladding. Therefore, since the appearance of panels with imitation stone, which happened not so long ago, the issue of finishing pile foundations is almost always resolved unambiguously. In any case, if the distance from the soil to the grillage is not very large, building walls does not make sense from the point of view of economy.

Another thing is when the lower crown of the house is one or more meters from the ground. In this case, there is a space that can be used at least somehow, for example: to store hoses, brooms, rakes, and other garden tools there. Then the walls should be made more durable, and the door can be built in them.

So far, I have decorated the brick foundation at my home with plastic panels. This is the easiest way to finish, but only they can crack over time.

Sweat is plastic on the exterior of the house, especially at the foundation level. I would not apply. There were just some cases from life when all sorts of not good midges settled in the profiles of plastic panels, especially wasps. Well, if you do it with a plastic cladding to soundly caulk all the holes.The best in my opinion, in terms of quality, is either a decorative stone or a burnt decor, of which an incredible amount is now.