Tiling the pool: finishing methods

A design such as a pool can be indoor and outdoor. Almost always performed facing the pool with tiles.

All this is due to the fact that the tile has excellent characteristics.

The content of the article

Varieties of pools

To date, the pools that are on the suburban area can be functional or decorative. Their shapes are quite diverse, as are their sizes.

Features and specifications:

- They are made, as a rule, in monolith or with the help of bricklaying. Other building materials are sometimes used.

- If the pool is for decorative purposes, then its lining can be performed by any modern finishing materials. If there is water in it, then it is imperative that they are moisture resistant.

- If the pool is functioning, then during its construction it is necessary to comply with all safety standards. Depth can be any.

It is only worth considering that the materials for facing such a design must be strong, reliable and moisture resistant.

Tip. For pool lining always preferred are those materials that are resistant to various kinds of chemical and cleaning agents.

Most common way pool finishes- Tiling pool.

Types of tiles for pool decoration and their characteristics

Tile for pool lining may be ceramic.

In turn, it is divided into:

- Clinker.

- Porcelain stoneware.

- Mosaic.

Material Details:

- These all materials are made on the basis of clay dough, only they go through different stages of production.

- Ceramic tiles for lining pools by technology undergo one or two firing. The tile with double firing has high strength, as its structure becomes denser.

- In size, it can be different. From this came the name of the tile "mosaic".

The surface cladding is made of small ceramic tiles, the size of which can be:

- 10x10 mm.

- 20x20 mm.

- 30x30 mm.

Note. There are options for such a material when a certain number of small tiles are attached to special grids and already in this form the material is mounted on the surface.

The size in this case may be:

- 20x30 cm.

- 30x30 cm.

All these are standard sizes of simple ceramic tiles.

Clinker and porcelain tiles in their properties are quite similar:

- If the clinker consists of clay dough with various special additives and dyes, then in addition to all this, feldspar is added to the porcelain tile during the production process, which gives the material high strength. It is involved in the formation of natural granite, which has the same characteristics as porcelain stoneware.

- The sizes of such tiles can be both small (20x20 cm, 30x30 cm, 60x30 cm), and quite large (60x60 cm, 70x50 cm, 90x90 cm). The latter version of the tile parameters is often used to finish the bottom of the pool bowl.

Pool facing tiles can have a surface:

- Flat or structural.

- Embossed or roughened.

- Matte, glazed or glossy.

More details:

- On the surface itself there can be imitations of other finishing materials or just images, which, with a certain amount of tiles, fold into large panels.

- The color scheme of ceramic tiles is quite interesting. There are neutral shades of the surface, but there are also very bright, which are usually found on the surface of the mosaic.

- Mounting the mosaic is quite difficult, since each element on the surface must be aligned exactly so as not to spoil the entire design. The simplest and fastest installation is characterized by standard ceramic tiles - 20x20 cm. Or 30x20 cm, 30x30 cm.

How to choose ceramic tiles for pool decoration

Ceramic tiles for facing the pool according to production technology must go with rounded corners.

Unfortunately, not all modern manufacturers know this process of manufacturing the material. For this reason, the tile has smooth angles.

Tip. In order to make the use of the pool safe, it is better to give preference to tiles with rounded corners, since it will not be dangerous if it is hit due to the absence of sharp corners.

In order for the pool ceramic tiles to be of high quality, there are a number of criteria by which it is worth choosing a material:

- Necessarily the tile must be in one batch, since in case of lack of it, tile from other batches may have differences in the shade of the surface.

- All corners of the material should be in the same plane. If this is not the case, then high-quality installation of the tile will fail.

- The thickness and dimensions of the tiles should be as described on the packaging.

- Storage of the material should be in appropriate conditions (it depends only on the seller).

- The surface of the tiles should be free of cracks and visible design deformations.

- On the tile itself at the edges there should not be chips or other defects.

- Well, the main criterion will be the price. For clinker and porcelain tiles, it is quite high. The most affordable are simple ceramic tiles or mosaics.

Tip. When buying tiles, it is worthwhile to ask the seller for product certificates to verify the authenticity of the material.

Properties and technical parameters of ceramic tiles

The most important technical indicator of ceramic tiles will be its moisture resistance. It freely withstands moisture.

It is also peculiar to it:

- Practicality, as the surface does not absorb dirt. On the tile of various kinds of pollution and bacteria can only remain on the surface and not penetrate the structure of the material.

It is cleaned quite quickly and simply using cleaning or chlorine-based products. - Strength, as it is able to withstand quite large loads and does not deform under the mass of water that fills the pool.

- Durability. Tiles can be used for 30 years. In some cases, the life of such a material reaches 50 years.

- Wear resistance. Throughout the entire period of application of the finish with ceramic tiles and various effects on it, its external design does not change, and the properties remain the same.

- It does not burn and freely tolerates very high and very low temperature conditions. She is not afraid of temperature changes. The only thing is that it warms up for a rather long time, but then it cools for a long time too.

- It has an attractive appearance and affordable cost.

- Due to the fact that the pool is lined with ceramic tiles, it also has the same technical characteristics.

The installation of ceramic tiles is quite simple and easy to do yourself. To do this, you do not need to have special knowledge, only you need to prepare the surface.

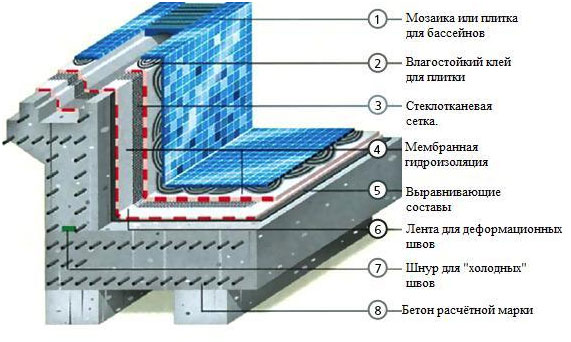

Surface preparation for the installation of ceramic tiles

In order for the pool lining with ceramic tiles to be of high quality and last a fairly long period of time, it is necessary to prepare the surface.

Tip. Install the tile only on a flat surface. All this is due to the flat back of the material, which is attached during the installation process.

In the preparatory process is carried out:

- Surface cleansing.

- Aligning her.

- Padding.

- Only after this is the pool lined with tiles.

Work:

- It is necessary to clean the surface of old layers of plaster or other means. If there is paint on it, then it must be removed using a special tool.

Then the surface is well cleaned. In some cases, professionals are advised to wash it with mild cleaning products.

Tip. After such work, the surface should completely dry.

- Surface leveling is carried out using moisture-resistant plaster or concrete mortar. You can use both.

Only applying layers of plaster will be much easier, because in the event of surface defects after such work, they are quite simply eliminated with sandpaper. - It will not be possible to carry out such work with a concrete solution, since it has a more dense structure, which cannot be processed with sandpaper.

Then a primer is applied to it. For the proper use of such a tool there is an instruction on the package.

Rollers or brushes are used for such work. The surface must be given time to absorb the product.

It is necessary for a more durable installation of ceramic tiles, as it provides a reliable bond of the adhesive solution and the surface itself.

Installation of ceramic tiles

Tiling pools is performed using:

- A special adhesive solution that freely withstands moisture.

- Tile cutter, which cuts the tile if necessary.

Tip. During such work, safety precautions must be followed. A mask or respirator is put on the face, which will protect the respiratory tract from dust when cutting material.

- Construction level in order to ensure smooth installation of each ceramic tile.

- Tape measure and pencil.

- Putty knife or other tool for applying glue solution.

The installation of ceramic tiles is shown in the video. Upon completion of work, all masonry joints are coated with a special agent - putty.

It should harmonize in shade with the design of the surface of the tile. As a rule, white putty is neutral.