Finishing a pool with foil in a matter of hours

Why is the pool wrap finished and what kind of load can this material withstand? Is it not better to turn to old and not forgotten materials, the price and durability of which suit many customers.

In reality, it turns out to be much more complicated and can not do without additional information.

The content of the article

Aesthetics or necessity

Based on the information that concrete is not a waterproofing material and its structure does not allow “holding” water, the idea arises of the need for waterproofing. These are materials, labor costs, appropriate payment, if there is no possibility and desire to complete the construction with their own hands.

We returned to the source of the problem and found out that the film is used in certain cases:

- The pool is built, has been in operation, but is leaking.

- Saving on the implementation of waterproofing has led to the fact that the construction of the pool was made using accelerated technology without it.

- There are no problems and troubles, it requires an inexpensive and simple pool decoration from modern esthetically attractive material.

Types and colors of film

Processing of raw materials using modern technologies allows the production of a variety of fairly attractive polyvinyl chloride materials. They belong to very interesting types of coatings with non-toxic properties, durable in use, with a surface that does not attract dust, hygienic and easily washable with warm water.

They make up a whole group of polyvinyl chloride (PVC) roll materials:

- PVC decorative finishing film.

- Fascinated on a paper base.

- Foam, PVC film, foamed, also on a paper base.

- Winisten and other materials.

The finishing film used for swimming pools differs in colors, but standard blue prevails, or the color for a white-blue mosaic. The service life of a film made of a sufficiently strong material exceeds 5 years or more.

One of the types is selected depending on financial capabilities:

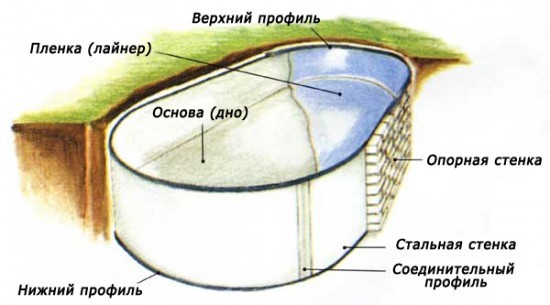

- Unreinforced PVC film 0.65-0.85 mm thick. It belongs to simple and cheap materials, does not have increased strength and can be used on the decoration of prefabricated pools.

- Reinforced film with a thickness of 1.5 mm. Demanded and popular film for swimming pool decoration.

Extra strength in it is provided by polyester threads. The film is able to withstand the load and not be deformed.

It is used in reinforced concrete and caisson pools, where the surface of the bowl serves as a supporting structure and can withstand high pressure. It is enough to recall that a capacity of one cubic meter, at a temperature of + 4 ° C, contains a mass of water equal to a ton. - Anti-slip film with a ribbed surface to eliminate slipping. Recommended in family pools where adults splash around with their children.

- When choosing a PVC film, you should pay attention to the acrylic coating. It is bactericidal and does not allow bacteria and algae to fill micropores.

Practice has proved that the service life, color, elasticity of an acrylic-coated film is twice as much. At a lower cost, varnished membranes are produced, which are a mixture of acrylic and polyvinyl chloride that look similar to an acrylic surface.

However, mixing several components reduces the effectiveness of the material properties.

Caution: PVC film is easy to repair after mechanical damage.

Her virtues

Finishing the pool with pvc film is used with great success and has become very popular not only among homeowners, but also among summer residents who decided to build a pool on their own site.

- The cost of the film is three times less than the ceramic finish and mosaics and does not make you spend heavily on your pool.

- In most cases, customers prefer a two-layer film with a thickness of 1.5 mm. Between the layers, it is reinforced with a special geotextile fabric.

- The outer layer is treated with chemical compounds that reduce the vital activity of microorganisms.

- The production of films possessing the properties of repelling limescale, dirt and color preservation due to resistance to ultraviolet, salts and chlorine has been mastered.

- Refers to a very fast finishing method, significantly compressing time and financial costs.

- The film simultaneously performs two functions. It serves as a waterproofing for the surface and finishing material, saving the same money and time.

- The durability of the material and its tensile property, work and serve as additional protection. For example, we can attribute its ability to withstand cracks of several centimeters in the pool bowl.

- It withstands extreme temperatures both external and internal.

disadvantages

- Loss of gloss, color and visual appeal after a long service life.

- The lack of a variety of colors and shades, so you have to choose from what is offered.

- A wonderful appearance is spoiled by noticeable, docking seams.

- The film can be ruined when using the pool, and it is subjected to mechanical damage.

Film application technology

Most often, people prefer to turn to professionals with special knowledge, equipment, materials and the ability to apply them. Sometimes, after viewing photos and video materials, the decision comes to use your strength, then a brief instruction on how to complete the process will not be superfluous.

For successful installation of the film, it is necessary to comply with all installation requirements, stock up with the necessary tools, materials and perform work at certain temperatures.

Attention: Best of all, the film “grabs” on a hot day, so it is better to install PVC at a temperature of + 15 ° C and above.

Tools

- Apparatus for welding (leister).

- Solvent having quality properties.

- Hammer drill.

- A sharp knife and a clamping, silicone roller.

Finish

The beginning of work is always characterized by bringing and preparing the surface in order:

- Cleaning of possible debris, dust, dirt.

- On the plastered surface, prepared for work, a geotextile substrate is glued. It reduces the friction of the film on the concrete surface of the bowl or other surface, which increases and increases the service life.

- The elastic glue and its use allow it to not crack after laying the film.

Attention: Make sure the film is clean, so as not to get a lot of “flaws” when soldering.

- Compliance with the exact dimensions when cutting the film will save material during operation.

- Finishing with a pvc film of the pool is very fast and can end in a few hours.

- If the film is correctly and uniformly stretched, the glue is distributed, the soldering and carbon deposits tools are constantly cleaned, and excess glue is removed from the surface.

The use of film does not limit the configuration of the pool. With it you can finish different surfaces, steps of different heights, various protrusions, protruding sides.

Two in one, such a definition is suitable for a PVC film - waterproofing and finish, like a kinder surprise. We can state the fact that there is nothing complicated and impossible in the decoration of the pool with foil.

A careful approach to small things and special equipment transform the faceless gray concrete and make the pool play with new colors and get a piece of joy on its own site.

Also on our resource you can find out how mosaic pool decoration.