Mosaic pool decoration: fashion or style

The key to success of any architectural compositions is the correct markup. You decided to arrange a pool on your site outside the city and watched a video on this topic?

We realized that the construction of pools does not belong to something from the realm of fantasy and, depending on the choice of the type of pool, takes a short time period. There is a real opportunity to do something with your own hands and gain useful experience next to specialists.

Before proceeding with surface finishing, it must be built.

The content of the article

Fabrication of the basic design of the pool

The bowl is not only called, but also refers to the basic design of the pool. It is the capacity for pools that holds water, which is by no means small in weight.

It is the reason for the enormous weight of water that causes a special approach to the manufacture of a pool bowl.

Which pool to choose

In the choice of pools, there are a lot of options that can cater to the most demanding tastes and requirements. You must view the photo, the proposed range, the cost of products.

So:

- If you plan to use the pool only in the summer, then for these purposes an inflatable pool is most suitable. Its advantages and benefits include quick, quick installation, relatively low price, mobility and portability.

Its disadvantage is the inability to withstand mechanical damage, inflatable pools have a small height and limited depth. - Behind them are frame pools with a more rigid structure, which allows to keep a depth of 90 cm to 1.5 m. The positive side includes the possibility of deepening them into the ground or assembling on the surface.

By and large, it is a complete substitute for the concrete pool on the site. The negative side is that the film serves as waterproofing and finishing material (seeFinishing a pool with foil in a matter of hours) retaining water.

They are divided into the economy option, where the film and metal sheet are thinner and the service life is 2-3 years. Frame pool with a thicker sheet and film and with a service life of 5 years.

They hold due to the pressure of water on the walls, have a round, oval shape or in the form of a figure eight. - Concrete pool, performed in two ways. In the first option, a finished bowl is purchased and installed, in the second case, the pool is completely poured out of concrete.

Attention: In order for the pool water to not bloom, it is necessary to ensure the circulation and filtration of water.

Frame pool and its assembly

So:

- A careful measurement and determination of the boundaries of the future pool is carried out using a primitive shovel and rope compass.

- On the recommendation of the designer, the diameter of the pool bowl should be 4.5 m, so a pit of a five-meter diameter and a depth of 0.7 m is created.

- Soil is selected and the base is formed. With light and loose soil, it takes half a day to make the foundation.

- Perfectly flat surface, equal and get, on a level.

Attention: To save the structure from mechanical damage, a 10 cm sand cushion is created with a careful tamping.

- The lower metal profile is assembled from the segments and laid along the diameter of the pit with an indentation of 0.4 cm from the wall.Frame assembly refers to simple designs, therefore, 2 specialists are supervised with installation and dismantling.

This is facilitated by the supply of components and spare parts in the kit. - The height for the pool was set at 1.5 meters and partially buried in the ground. The finished profile is inserted into the metal walls and secured by a transverse rail.

- From above, the circumference of the bowl is formed by a metal profile.

- The bottom of the pool is leveled with sand and at the final stage a polymer coating is laid and attached on top with special profiles.

- Carrying elements of the frame are installed around the circumference and secured with metal fasteners, mounted sides are closed from above by a profile and special overlays at the joints.

Concrete pool

A pool with full concrete pouring is cheaper in cost, although the volume of work performed is much larger than when acquiring a finished bowl.

There are certain subtleties in the sequence of work:

- The work is not done with concrete, but rather with reinforced concrete. High-quality reinforcement is carried out and reinforcement with a thickness of at least 12 mm is used, depending on the dimensions of the pool.

Attention: Thrust rods carrying the main load are constructed of 16 mm, and preferably of 20 mm fittings.

- The frame is tied all at once, so that the bottom and side parts make up a three-dimensional structure that can withstand a given volume of fluid.

- Pouring concrete solves a specific problem - obtaining a monolithic reinforced concrete bowl. Formwork must be performed in such a way that concrete pouring is performed at a time.

The inner formwork rises above the reinforcement for the free flowing of concrete under it. The formwork must be carefully strengthened, because concrete is a heavy material and miscalculations in the pouring process can lead to wasted waste mass. - A very important point - the execution of concrete pouring in one sitting is possible only with the purchase of a finished composition and it is better to use one or two in a mixer. It is better to purchase reinforced concrete, additionally reinforced with fiberglass.

About any concrete prepared manually or in a home concrete mixer is out of the question. - The filled and received monolithic bowl is left at rest until completely dry. Concrete does not immediately gain strength, for this it takes time and moisture.

Its strength depends on slow drying, and the bowl stands for a month, and preferably two. In this case, the first two weeks without fail the bowl is moistened with water daily.

To reduce the loss of water from concrete will help polyethylene, which can cover the surface. - Next, you need to complete the work phase associated with waterproofing the outside and inside.

- External waterproofing solves the problem of groundwater penetration into concrete, while internal waterproofing does not allow liquid from the pool to penetrate outside. Waterproofing outside is standard.

Processing with bituminous mastic is carried out, and then roll insulation is glued in two layers. A second layer is deposited onto the horizontal lower layer deposited by the gas burner, but only the vertical layer, not forgetting to overlap individual strips of material.

- The waterproofing of the bowl from the inside is carried out by special dry mixtures in two layers, applied in opposite directions. The solution is applied with a spatula in a thin layer, the corners are carefully patched.

Previously, waterproofing of the surface was carried out with the addition of liquid glass to the cement mortar. A very effective mixture with one minus is the quick setting and solidification of the mixture.

Attention: The modern construction market offers special dry mixes for waterproofing, which serve as the ideal basis for further tiles or mosaics in the pool.

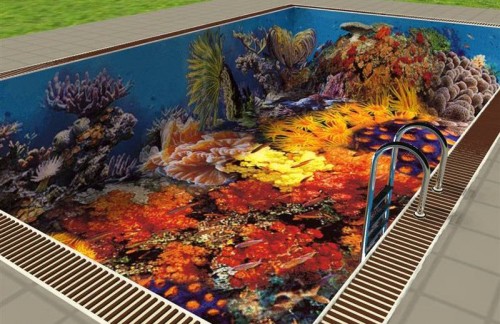

Mosaic for the pool

Mosaic refers to a reliable wear-resistant material suitable for pool finishes. It is customary to purchase glass or ceramic mosaics, special chic porcelain.

Mosaic pool lining refers to the final stage of the construction of a water structure. The choice of glue for the mosaic depends on the location of the pool - on the street and whether indoors.

The instructions on the package will tell you the properties, quality and application of the product.

So:

- The prepared mosaic for laying takes the form of a matrix consisting of rectangular chips (squares) glued to the grid or paper with the front side.

- Facing begins 1-5 days after surface plastering and the completed waterproofing.

- Mosaic is laid on a special glue or mortar of cement and sand.

Walls and their design

So:

- Mosaic decoration of the pool is carried out in horizontal rows and starts from the walls. Plumb bobbins and nails are used to install vertical beacons.

A horizontal line of fishing line with the familiar name “mooring” is hung on the upper edge. The fishing line moves row by row, controlling the straightness of the joints. - The neighboring tiles are oriented with the entire plane along the vertical cord and are settled to the desired line by lightly tapping the blade handle on it. The size of the facing seam is fixed by improvised elements of one section.

Attention: It is recommended to fill the joints with half the thickness of the tile and after laying a row, a flat rail is attached to the tile and upsets it to the required level.

- Counting the required number of full-sized tiles must be done before starting work. This will save you from unnecessary work on cutting material, the cladding will look neater and tile consumption will not increase.

The importance of obtaining a given pattern or symmetry requires starting the masonry from the middle of the row and ending the corners with halves or cut tiles. The formed joints are processed with a frost-resistant and moisture-resistant grout, combined with or fixing tiles.

The bottom and its design

Why go somewhere here and so good:

- Particular attention is paid to laying the bottom, which is not done in rows or in an “envelope”, but at the corners of a triangle. It is used in cases of floor irregularities in the pool caused by a bias towards draining the water.

- The drain hole is located in different places. If it is in the center of the pool, then the bottom is conditionally divided into 4 triangles along which the lining is made.

- Laying tiles in a triangle begins with a wall row without a slope.

- The lighthouse row is laid out perpendicularly to him.

- Horizontal lining of the surface of the triangle is carried out using incomplete tiles along the edges and constant reconciliation with tiles in the lighthouse row.

- The remaining triangles are formed in a similar way, that is, initially the wall and lighthouse rows.

- For grouting, special compositions based on epoxy resins are selected.

- For complete filtration, it is better to use a hinged system located in a small pit, and from it just two pipes drop into the pool for the intake and supply of purified water. The only difference from the built-in one, which creates problems with sealing the inlet and outlet pipes in the concrete bowl, is the pump power.

Finishing the premises of the pool is carried out according to the same principles as at the pool. Mosaic for pools is good because it allows you to create any ornaments and patterns, it can be lined with curved surfaces and hard to reach places.