Pool lining technology: materials and installation

The technology of the pool lining must always comply with all established safety rules. As a rule, only moisture resistant materials are used in such works.

The content of the article

What can be used to decorate the pool

At the moment, pool lining can be performed using:

- Ceramic tiles.

- Porcelain.

- PVC films.

Characteristics of materials:

- These materials are very practical and moisture resistant, which requires GOST to organize this type of room.

- But, correctly making the lining of the thicket of the pool is only half the battle, as the main design will be in the room.

In such works, practical and moisture-resistant materials are also preferred:

- Plastic lining.

- Siding.

- Ceramic tile.

- Wood (quite rare).

Pool decoration

Lining the walls of the pool and its bowl is most often done with ceramic tiles. Ceramic tile, this type of material is the most common for pool finishes.

Tiles can have various surfaces:

- Smooth.

- Glazed.

- Matte.

- Polished.

- Rough

- Structural.

Tip. The lining of the pool bowl is always done only with tiles with a rough surface, since it does not slip.

Features:

- A ceramic surface is made of clay dough, which during the production process passes through several stages of pressing under the influence of high temperatures and only then undergoes firing.

- In the case of a glazed surface during the firing process, glaze is already applied to the prepared base. That is, the tile already has a certain pattern.

- As for the design itself on the surface, that is, a variety of imitations of natural stones, masonry and other ornaments. The color scheme also has a large assortment.

- But, when using such a material, it is worth considering that it can only be mounted on a flat and high-quality prepared surface.

- The properties of ceramic tiles include moisture resistance and practicality. The material has been used for 15-25 years. The tile does not burn and is environmentally friendly material.

- Also, it is not exposed to temperature changes and is able to withstand a variety of chemical influences on its surface.

Facing the bottom of the pool and its walls can be performed by any size of this material.

There are such basic parameters of ceramic tiles that are used in cladding:

- 30x30 cm.

- 60x60 cm.

- 20x30 cm.

Tip. It is easier to work with standard sizes (20x30 cm). The tile is not large and is mounted quite simply on the surface.

What is needed for the installation of ceramic tiles

Facing the pool bowl with ceramic tiles is performed using:

- Mortar of cement or special glue.

- Small spatula.

- Building level.

- Cruciform lighthouses.

- Tile cutter.

- Decorative putty.

Tip. Before work, it is worth priming the surface for greater adhesion of the concrete mortar to it.

Directly inside the structure, the lining of the bowls of the pools is carried out and only then all the work goes to the walls.This is only if ceramic tiles of the same size are selected.

In other cases, you can start work from the walls of the structure.

Porcelain tiles for swimming pools

This material is very practical and stronger than simple ceramic tiles, although it is one of its subspecies. For this reason, quite often the pool floor lining is performed with porcelain tiles.

It has the same types of surfaces as ceramic, only slightly superior in value to it.

Qualities will also be identical:

- Practicality.

- Strength.

- Moisture resistance.

- Fire resistance.

- Frost resistance.

- The ability to withstand various temperature conditions (low and high).

Tip. The lining of the pool bowl should only be done with porcelain stoneware tiles with a rough surface.

But the lining of the walls of the pools can be with a polished and glazed surface.

Tip. It should be noted that when finishing the pool with porcelain tiles, it should also be around the structure (on the floor).

Installation of porcelain tile

Lining the walls in the pool with the use of porcelain tiles is carried out in the same way as with ceramic.

For this you need:

- Glue or concrete mortar.

- Putty knife.

- Building level.

- Tile cutter, only with a more massive blade, since porcelain stoneware is quite durable and its thickness exceeds ceramic tile.

Cross shaped beacons provide an even distance between each tile during installation. After full fastening on the surface of the porcelain tile, decorative putty of a certain shade is used.

PVC film

Pool lining technologies using PVC films can be varied. Some mount it on a metal frame, which after complete installation is treated with sealant and closed with ceramic tiles on top, and someone mounts it directly on the surface of the walls.

Characteristics:

- PVC film is very strong and durable. It is not able to absorb moisture and various impurities. It is cleaned very simply using a simple damp cloth.

- It does not burn and does not melt when exposed to high temperatures. Also, she is not afraid of chemical influences. Has a PVC film a large assortment of design of its surface.

- You can see whole sheets of such material, on which there will be an imitation of ceramic tiles or masonry, a variety of drawings and images. All this contributes to the fact that the lining of the walls of the pool and its bowl looked very original.

- The price of this type of finishing material is not too high, which makes it possible to use it not only for facing the pool itself, but also for finishing the room.

Installation of PVC film

The technology of pool lining using PVC film can be performed using:

- Construction glue, self-tapping screws, liquid nails.

- Building level.

- Clerical knife, as sheets of material are quite simply cut to the desired size.

- Sealant.

- Special skirting boards for mounting film.

- Interior and exterior corners of PVC trim.

Even a layman in this field will be able to do all the work with his own hands, since there is nothing complicated in them.

Tip. If the technology of pool lining involves the use of a certain frame for the installation of the material, then it should only be profile made of metal, since in the case of a wooden crate, if it gets under the finish, its deformation can begin.

Outdoor pools and the possibility of finishing

Outdoor pools differ from indoor pools only in that they are not indoors. The lining of the outdoor pool is no different from the inside.

Only moisture resistant materials are also used:

- PVC film.

- Porcelain tile.

- Ceramic tile.

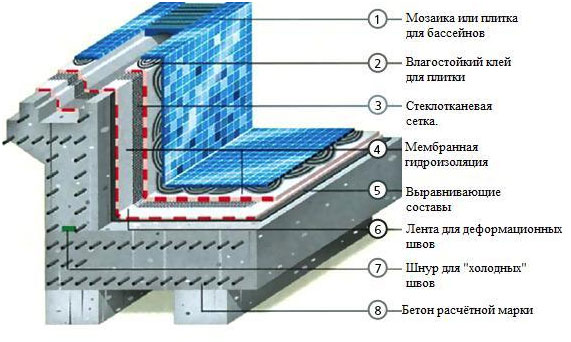

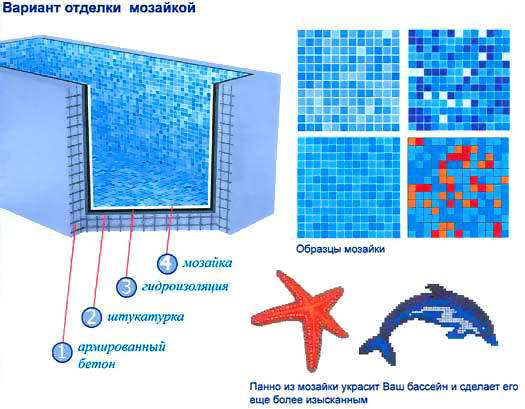

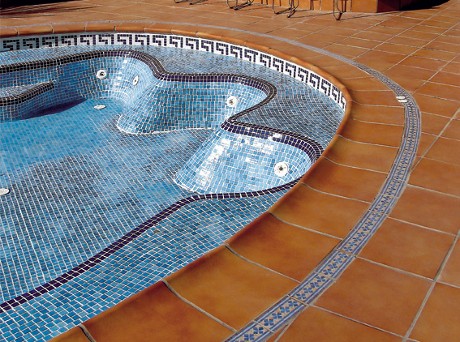

Very often the lining of outdoor pools is carried out with a mosaic, the size of which is 20x20 mm, and maybe in sheets of 20x30 cm. Here, all the main mosaic elements are already attached to the base, with the help of which fast and high-quality installation is carried out.

Finishing the room for the pool

It is desirable that the lining of the pool room is also carried out with moisture resistant and practical materials. Porcelain tiles are very popular in flooring, and siding or plastic on the walls.

Plastic and siding

According to their characteristics and properties, these are two identical materials. Only they can be in sheets and in strips, but technical indicators from this do not change.

These materials:

- Relatively strong and reliable.

- Practical, since they do not require special care for their surface, which does not absorb dirt.

- Moistureproof and fireproof.

- Freely withstand significant temperature changes.

- They also do not fade in the sun and can be used for 20 years.

Siding or plastic surface can be:

- Glossy or matte.

- Structural or rough.

- Flat and convex, concave and so on.

Tip. For the decoration of the pool there are no restrictions on the use of a particular surface of siding or plastic. An important role is played in her choice of the interior of the room.

Installation of siding or plastic

There is a specific instruction for such work. According to it, the crate is originally made on the surface - a kind of frame. As a rule, in damp rooms metal is used, not wood.

Works:

Tip. If a wooden frame is made, then after its installation, its surface should be painted to protect it from exposure to a humid environment.

- The material itself is mounted using self-tapping screws or a construction stapler, which secures the first plastic strips or siding sheets. Between themselves, the trim elements are fastened with special locks, which are located at the end of the materials.

Tip. Be sure that each joint of the strip or sheet must be treated with sealant, for greater tightness of the finish.

- At the top of the room, a starting strip is mounted for mounting the material. All corners are made using decorative corners made of plastic.

They are mounted after full installation of the material on liquid nails or using a stapler.

The whole process is quite simple and in the video you can see the installation of a plastic lining on the frame.