Mosaic pool lining: design ideas

At the moment, you can often find a pool lined with mosaics. This material helps to create a unique design for this design both outdoors and indoors.

The content of the article

Varieties of mosaics for pool lining

At the moment, mosaic for pool lining can be made of:

- Pottery.

- Natural stone.

- Glass.

Note. By their properties and characteristics, they are almost similar. They also do not have differences in installation.

What is ceramic mosaic and what is it made of

Ceramic mosaic is a tile that has a very small size. It is made from clay dough.

There are several manufacturing options for such material:

- With single firing.

- With double.

- Tiles that undergo firing in several stages have special strength.

The surface of the ceramic mosaic can be:

- Smooth or structural.

- Embossed.

- Matt

- Glossy.

- Glazed.

Note. As for the external design, the material has a wide range of shades. Also made of small tiles is a panel on the surface.

Quite often, this material design is used to decorate the walls and bottom of the pool.

Ceramic mosaic for pool lining may have the following dimensions:

- 15x15 mm.

- 20x20 mm.

- 30x30 mm.

- 50x50 mm.

- 10x10 cm.

Large sizes of the material are mainly made on a special grid, which has the standard sizes of ceramic tiles: 20x30 cm or 30x30 cm. Mounting this type of ceramic is quite simple.

Properties and advantages of ceramic mosaic

The main property of ceramic mosaics will be its price. She is quite affordable.

It all depends on the manufacturer and production technology.

Ceramic tile:

- Moisture resistant, which makes it possible to use it for pool finishes both indoors and outdoors.

- Able to withstand fairly large mechanical and physical stresses.

- Does not respond to temperature changes and direct exposure to sunlight.

- It is wear-resistant, since it does not change its structure and appearance during the specified service life.

- It does not burn, as during the production process it is exposed to high temperature and thus the material is hardened.

- It is not exposed to climatic and weather events and changes.

- It can withstand both low and high temperatures.

Installation of this type of finishing material is labor intensive. Especially if small tiles without a grid are used, and so the work can be done with your own hands and not involve specialists in this field.

Mosaic made of natural stone and glass

Pool lining mosaics made of natural stone or glass are rarely used. Most often, these types of materials are used to decorate decorative pools, since the price of this cladding is quite high.

Mosaic from natural agglomerate is quite strong and reliable. It has an aesthetic appearance.

The surface of such a material may be:

- Smooth.

- Chipped.

- Sawn.

- Polished.

- There is also a glossy or matte finish.

- Onyx or granite are very often used for decoration of pools and artificial reservoirs.

- Marble cladding is very rarely used. This is due to the high cost of the material.

- Glass mosaic can only be with a flat surface. The appearance itself is quite diverse.

All specifications and properties are similar to ceramic mosaics:

- Durability and practicality.

- Wear resistance and fire resistance.

- Moisture resistance and ability to withstand temperature changes.

- Materials do not fade in the sun and are frost-resistant.

Note. The thickness of a natural or glass mosaic can be any, starting from 0.5 cm. Only with such a thickness, you should not use it on the floor surface or at the bottom of the pool, since it is not able to withstand the mass of water in the tank.

What type of mosaic is best for pool decoration

The most practical and reliable option for decorating the pool is ceramic mosaic. It is used to decorate the bowl itself.

On the top, you can use glass mosaic, and from natural agglomerate.

Tip. To diversify the design of the pool, it is best to use not one type of material, but several. It will be possible to make various kinds of drawings or panels on the surface.

It is not recommended to use a mosaic on such a grid for such works, since the grid can freely perceive the effects of a humid environment, and because of this, the fastening of the tile on it weakens over time. Thus, the surface finish begins to deform.

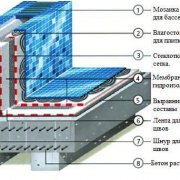

Preparatory work for the installation of ceramic mosaics

The pool mosaic is based on high-quality preparatory work on the surface. They consist in leveling and priming.

In order to level the surface is used:

- Plaster.

- Mortar concrete.

Tip. If concrete mortar with the use of various special means can become moisture resistant and not collapse under the influence of temperature extremes, then in order to use plaster it is necessary choose its type correctly - moisture resistant.

What you need to provide:

- At the moment, it is possible to add funds to ordinary plaster that will increase technical performance. True, this does not replace plaster, which has similar properties and has factory manufacturing. This material will be considered better.

To smooth the surface, starting and finishing plaster is used.

To apply such funds you will need:

- Two spatulas of different sizes (one large, the other smaller).

- Construction level for even application.

- Sandpaper (with large and small cells).

Tip. To finish it better, you can use a special grid for plastering the surface, which is fixed to the walls of the structure with rivets or after applying the first layer of the product.

Work:

- Also, special beacons are installed around the entire perimeter of the future decoration. First, “start” plaster is applied to the surface.

- Its layers should not be too thick, since after the installation of the finish finish the layers can move away from the surface, which will spoil the appearance. Each layer that is completely dry is treated with sandpaper with large cells.

- Then, on the surface of the starting plaster, a finishing agent is applied - finishing plaster. It undergoes a similar treatment, only sandpaper with small cells is used for this.

- This choice of sandpaper is due to the fact that the structure of the starting plaster has large grains, and the finish - small ones.

Tip. Since plaster of any kind is sold only in powder form, there is an instruction on the packaging of the product to make a solution out of it.

According to it, a certain amount of liquid is added to the container and powder is poured there. Everything is mixed with a construction mixer to give uniformity to the mass.

- The number of layers of both start and finish plaster on the pool surface depends on the size of the defects. As a rule, the starting plaster is applied in three or four layers, and the finishing - in one or two.

- Concrete mortar is often used. Aligning defects that have appeared during the work will not be possible with sandpaper.

For this reason, it is worth doing everything very efficiently and accurately. - A solution is prepared from cement grade 400, sand and water. All proportions of such ingredients depend on the size of the pool.

On average, 2 buckets of sand are used per 1 bucket of Portland cement. The amount of water depends on the desired consistency of the solution.

Tip. This tool is best made in a concrete mixer, which can make the mass of the solution homogeneous.

After all this, the surface is treated with a primer and a brush or roller with natural pile is used as a tool.

The primer must be absorbed. It will take several hours and then you can proceed to the installation of ceramic mosaics.

Ceramic mosaic installation

Cladding technology pretty simple. For this, concrete mortar or special glue for ceramics or porcelain stoneware is used.

Tip. Such means for fixing on the surface of ceramic mosaics for finishing the pool must be moisture resistant.

For work you will need:

- Cross-shaped beacons that provide an even distance between each decoration.

- The construction level, which helps to expose the tile and evenly fix it on the surface.

- Tape measure and pencil for measuring material.

- Tile cutter.

Note. The latter tool is used to mount mosaics quite rarely.

Work:

- The installation of the material must begin at the bottom of the pool. Lay tiles in several rows.

After this, you need to let the solution gain strength and only then continue the installation of subsequent rows. - The concrete mortar is applied to the surface. On the back of the ceramic mosaic, you do not need to apply the product.

Tip. When installing ceramic mosaics, cross-shaped beacons can not be used, since in most cases the installation of decoration elements is carried out closely.

- If special glue is used, then the use of decorative putty for masonry joints is not required.

If the masonry is performed on concrete mortar, then after completion of installation it is necessary to process each seam with a decorative agent. Used for this special small rubber spatula.

So that there are no questions about how to properly install ceramic tiles of any size for pool lining, you can watch the video.

With large areas of the basin space, it is quite difficult to lay out with mosaics selecting small pieces, then either use a larger ceramic tile or even simply cover it with polymer.