Materials for facing wooden houses - the main types

Exterior finish solves several problems at once. This is a change or improvement in design, increased heat saving, protection of load-bearing structures from external factors, increase in the duration of operation of the building.

Wood is especially in need of decoration, as it does not withstand the damaging atmospheric and biological effects. Therefore, it will not be out of place to talk about what materials for cladding wooden houses are used in our time.

The content of the article

Types of cladding

According to installation technology cladding materials the facades of wooden houses are divided into two groups: wet and hinged cladding. The first includes those for the installation of which building mixtures are used - concrete, plaster, cement-based adhesives.

The hinged cladding is mounted using hardware on a frame fixed to the walls.

Materials for wet cladding

These include facade plastering, brick or tile lining - all these types of exterior decoration require the use of dry mixes diluted with water.

So:

- Plaster is not the best facing material for a wooden house, but acceptable. In former times, such houses were plastered with clay compounds, followed by whitewashing.

This method is sometimes used today, as very affordable and budget. But more often, ready-made stucco mixtures based on mineral or acrylic are used, which are applied to the walls using a crate or reinforcing mesh.

For reference. Mineral plaster based on Portland cement is more durable, but does not differ in the richness of the color choice. Acrylic plaster without repair will last less, but it allows you to choose a different color and texture of the surface and does not interfere with the air exchange of wooden walls.

- Facing brick. Going through the different types of cladding of a wooden house, you can stop at the brick only if such decoration was provided for at the stage of designing and erecting the foundation, as it creates a decent load on the base and the grounds located under it.

And under light wooden buildings, the foundation is usually not laid the most powerful. As for the advantages and disadvantages of brick cladding, the first certainly include reducing the risk of fire in a wooden house, improving its thermal insulation, reliable protection against external aggressive factors and giving the structure a respectable appearance.

Disadvantages - the huge complexity of the process and the high price of both the material itself and its installation.

Note! When performing facing masonry, it is necessary to deviate from the wall or insulation fixed on it by at least 4-5 cm. The resulting gap is needed to ensure natural ventilation of the wooden walls, the removal of water vapor and condensate. Masonry should be done using metal mortgages that tie it to the main walls.

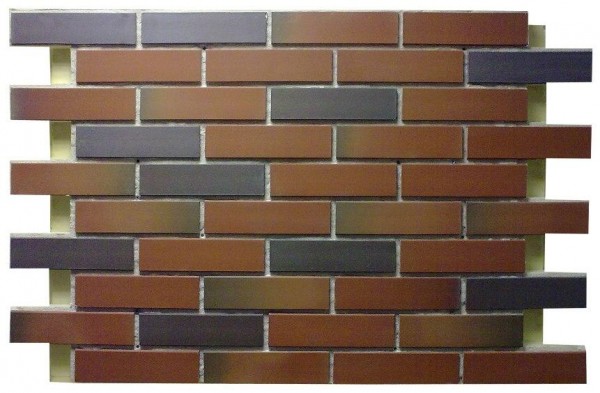

- Facing tile. Its varieties are many. The raw materials for it are clay (clinker, ceramic tiles, porcelain tiles) or a cement-sand mixture (artificial stone) with various additives that affect strength, frost resistance and appearance.

Externally, these cladding materials for wooden houses can imitate brick, wood, natural stone of various breeds. Tile mounting method - gluing on a pre-aligned surface.

Alignment can be done with plaster or sheet materials, for example, cement-bonded particleboards. In the latter case, the finish is considered combined, since the DSP is mounted on the frame indented from the bearing walls.

Materials for curtain wall cladding

Hinged facades, regardless of the materials used, are mounted easier and faster than wet. At the same time, they allow you to insulate the building, improve its sound insulation and performance, give any desired look.

For wooden buildings, this type of finish is more preferable, since it eliminates the contact of wood with moisture during installation, does not interfere with free air exchange, and allows you to forget about maintaining the facade in good condition for many years.

Many homeowners are also attracted by the opportunity to clad the house with their own hands and save on finishing work, while the installation of wet facades does not tolerate an amateurish approach.

So:

- Plastic cladding materials of wooden houses are vinyl siding and PVC panels, which are also considered a kind of siding, but have a different shape and greater thickness. Polyvinyl chloride is a synthetic product characterized by high resistance to moisture and aggressive environments, frost resistance, fire safety. The panels made from it have a very low weight, therefore they do not create a significant load on the foundation.

They are easily mounted, do not require maintenance during operation, and in case of damage, individual panels can be quickly replaced without dismantling the entire lining.

For reference. PVC panels with a decorative surface imitating bricks, natural stone, granite, etc., are called basement siding. But they are widely used for the complete decoration of facades. Due to the greater thickness than conventional siding, they better withstand mechanical damage.

- Thermal panels. These are perhaps the most popular materials for cladding of a wooden house.

Consisting of sheets of polyurethane foam or expanded polystyrene with a decorative front surface of clinker tiles or marble chips, they are an excellent insulation. Their use greatly simplifies and reduces the time required for thermal insulation and cladding of buildings, since instead of two operations, only one is performed.

The surface they create due to the original connection of the thermal panels is free from joints, outwardly it looks exactly the same as brick or stone cladding, but at the same time it has better heat and sound insulation properties, less weight, and resistance to weathering.

- Facade panels based on OSB and LSU. Outwardly, they are very similar to thermal panels, but their front side made of brick tiles or artificial stone is glued not on polyurethane, but on oriented-strained or glass-magnesite sheets.

Choosing this material, you get a high-quality finish of the house with tiles, but at the same time avoid time-consuming "wet" work. The installation instructions for the panels provide for their fastening to vertically arranged frame guides with self-tapping screws in inter-tile seams with their subsequent termination.

- Block house. It will appeal to those who want to preserve all the advantages of a wooden house and protect it from external influences.

This material is a panel of dried and impregnated with special wood compounds, the inner side of which is flat, and the outer one is made in the form of a log. Elements are interconnected according to the principle of lining - using the groove-comb system on the side faces.

- Wood-composite panels are facing materials for a wooden house, possessing all the advantages of natural wood, but without their drawbacks. Made from a mixture of wood chips with thermoplastic polymers, they have an ideal surface, do not absorb moisture, do not burn, do not rot, spread mold and damage by insects.

- Fiber cement panels. Made of cement, cellulose fiber and various synthetic and mineral additives, they are environmentally friendly material with the highest performance characteristics. This is incombustibility, impact strength, resistance to mechanical damage, durability, inertness with respect to aggressive environments, etc.

Common to all these types of finishes is the installation method - on a system of guide profiles with a ventilated gap between the wall and the cladding. For each type of panel, a different frame is mounted, the design of which depends on the dimensions, shape and weight of the lining. Read more about this on the video.

Conclusion

The article describes far from all the options for facing wooden houses. In addition, in our time, new products periodically appear on the construction markets that amaze consumers with high quality, practicality, and, best of all, at a reasonable price compared to traditional materials.

I have never heard of thermal panels and wood-polymer composite, it will be necessary to clarify. Now I’m just looking for a block house, because the master who is engaged in decorating the house recommended this material, moreover, from larch. I was very surprised by the huge selection of colors and textures of various types of siding, because from the very beginning I thought that there was the usual “wood look”. Now I’m thinking, is a wood-polymer composite better? It looks like a tree, but it’s fireproof and is not interesting to bugs; there’s no need to impregnate it. Initially, I did not consider the “wet” cladding, it is essentially just a reconstruction of the house, if it is bricked and the foundation is strengthened. It pulls along with the alteration of the basement, water supply, sewage and other things.