Facing columns as an element of decor

Columns are one of the most attractive and original design options, and not only the interior, but also the facade of the building. The days when these when architectural elements were exclusively constructive are long gone.

Nowadays, they often have purely decorative features. Therefore, today designers use a variety of materials for facing columns.

What kind of materials are these, and how they are used to finish, and this article will be discussed in our article.

The content of the article

Column as part of the interior

If we talk about city apartments, then there is a column (seeColumn decoration: doing it right) phenomenon is extremely rare. The fact is that this element most effectively looks in high spacious rooms.

Such apartments can still be found in houses of Stalinist construction, as well as in some houses built according to individual projects.

So:

- The bulk of the multi-storey housing stock does not differ in the particular spaciousness of the premises. Although, this fact only made designers think how to fit the column into a small room so that it does not take up much space.

- So there were decorative columns, which can be a half-column adjacent to the wall along the entire height. There are options for low columns, which serve, for example, as a stand for a flowerpot with plants, a lamp or a bas-relief.

Use such techniques in the design of premises in such architectural styles as antique, empire, rococo.

Hyperproc column with cladding

Mount decorative columns made of polyurethane, polystyrene. A special role in this design is played by the gyro.

Plasterboard can be used to veneer existing columns or create decorative ones:

- And they can be quite complex configurations. For example, in the photo below, the column is, as it were, cut into pieces, which allows you to use it not only decoratively, but also as shelves for any small things.

Take a note and try to do something similar in your home!

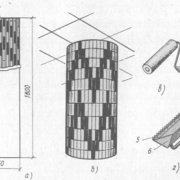

- For those who are familiar with the general rules for working with drywall sheet, it will not be difficult to make such a design: read the articles, watch the video. The only thing you need to know is that a regular sheet of hyproc is not suitable for such work.

- There is a type of drywall (seeGypsum plasterboard cladding: finishes), called designer. Such a sheet is thinner, reinforced with fiberglass, and bends remarkably.

This type of drywall is used for the manufacture of curved shapes with a small bending radius, which include round columns.

- Material for column lining from a drywall you can use a variety of: paint, embossed wallpaper, cork, flexible acrylic tiles, and even natural stone. Pay attention to the picture below: here, for the decoration of the columns, a material called “flexible facing stone” was used.

- You ask, what kind of material is this? This is a roll coating, which is also called stone wallpaper.

This material is made from the finest veneer of natural stone, in this case, sandstone, which is glued to a textile base. - Such cladding for columns, especially hollow ones, is the best choice. It has a low weight, and the price of this material is much lower than that of natural stone.

And the appearance of the column, as you see, is in no way inferior to the stone cladding. In the production of stone wallpaper, the original texture and color of the geological cut of sandstone found in the deposits are fully preserved.

- And the texture is preserved thanks to the technology of its production. The surface of the stone formation is leveled, impregnated with a special adhesive, and the fabric is fixed on it. After a while, it is removed along with the upper layer of stone.

- The resulting material has a thickness of not more than three millimeters, and can be not only rolled, but also in the form of tiles of various configurations.

- Anyone will be able to do such a lining with their own hands, because special training is not required here. And most importantly, you can finish the column of any configuration, and not only the column, but also any other structural element of the room.

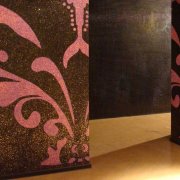

- By the way, painted columns also look good. In the picture above: decorative plasterboard columns painted with dark mother-of-pearl paint, creating a contrast to the wall and floor coverings.

But you can go further - take a decorative paint, with which the surface of the columns can look like the surface of marble, leather or wood.

If such columns are not made of drywall or polystyrene, but are made of bricks, or made of monolithic concrete, you can also decorate them with Venetian plaster. Of course, such decoration will be the most expensive, but after all, houses have a considerable cost.

Beautiful home - chic interior!

Tile and decorative stone

A completely different level of difficulty is facing the columns with stone and tile. If you do not have the necessary skills, you will at least need detailed instructions - it can be applied in both cases.

So:

- If the simplest option is formed: a square column - facing with a stone, in this case, can be performed regardless of its shape. After all, stone for cladding is produced in the form of elements of various configurations.

- It can look like tiles of standardized sizes, and stone "noodles", breccias, wild stone, and, of course, mosaics. The smaller the cladding elements, the easier it is to clad the surface of a round or multifaceted column.

- From this list, it is most convenient to use a mosaic for this purpose. Yes, and the aesthetic value of such a finish is the highest, because the mosaic can be not only stone, but also ceramic, glass, smalt, mirror - there are a lot of options.

- It is very convenient for finishing columns, even round ones, to use mosaic tiles. It represents a certain set of elements fixed on a soft substrate, which makes it possible, if necessary, to easily separate any part of them.

Naturally, such a tile bends without problems even radially, even at an angle.

If there is an irresistible task to stone a round column with stone, then this is easiest to do with artificial stonecast over the radius of your column. You see a sample of such a cladding in the image above.

Similar materials for facing the columns can be cast at home, only a mold is needed.

Facing the square column

So, we will briefly consider how to tile a square column. In fact, this is a fireproof lining, so it can also be used to decorate chimneys that look like columns in the interior.

So:

- The technology for laying stone or ceramic tiles, in general, does not differ from wall or floor cladding. The peculiarity of this process consists only in the installation of beacons, and the fastening of the guides.

- The verticality of the structural column is checked using a plumb line.If the column is mounted from gyro, the levels are checked during the installation of the frame.

In any case, the surface should be prepared for the finish: smooth, and primed. - Using a metal ruler, the axes of the faces of the column are determined. In the upper part of the side, one tile is reinforced on the side.

Further, the distance from the axis to the edge of the face is measured, taking into account the thickness of the tile. Using a level and a plumb line, this mark is transferred down the columns, and another lighthouse is strengthened. The same thing needs to be done on the other hand.

- Cords are pulled between the lower and upper beacons, which will symbolize the surface of the lining. Then the tiles are prepared: they are laid out across the width of the column in order to calculate how many full-sized tiles will fit, and how many will be additional.

- Partial tiles are immediately cut, but so that each segment in width is half as much as necessary. This is done in order to avoid the asymmetry of the masonry.

Each half of an incomplete tile is laid on both sides. - In that case, if the floor covering is to be installed after finishing the column, then under the lower row of the column lining it is necessary to put a bar, the thickness of which will correspond to the level of a clean floor.

- Laying tiles start from the bottom, “seam to seam”, and lead it along two opposite sides. Then go to the facing of the second pair of faces.

To make the corners of the column beautiful, they are faced with tiles with blockage of faces, or corner elements with a pattern.

- Lining of multifaceted columns is approximately the same. Such structures most often adorn the facades of administrative buildings, and are finished with natural stone of valuable species: marble, onyx, granite, travertine.

- The stone cladding for them, as a rule, is made to order, and the width of the stone tile corresponds to the width of the column face, as you can see by looking at the example given by us.

- There is still such wonderful material as facing brick. But it is quite heavy in weight, so the brick is not made to finish the columns, but their construction. That is, they are used constructively.

If the column in cross section is large, inside the masonry can be made of building bricks. In this case, for laying out the outer layer, decorative brick is used for facing columns: colored, figured, embossed.

It is used so that the surface does not have to be plastered or painted, plus a beautiful shape. Fortunately - there is a choice of facing brick, and considerable.

Paneling of columns

If the column does not have a circular cross section, but a square, or, for example, rectangular, the number of material options that can be used to clad it increases many times. And such columns in residential buildings are more common - their role is often played by chimneys from fireplaces passing from below, through all floors.

So:

- Take at least different types of wood-polymer panels. Facing with wood of columns, in this case, is carried out in combination with walls or a ceiling structure.

This allows you to create an original interior, such, for example, as in our example below.

- But still, paneling columns, it is more an office design option. Moreover, there are columns in almost all major shopping and entertainment centers, public buildings, which include stations, airports and underpasses.

- In such buildings, the columns are structural elements that carry certain loads. Often, the main task of decorating columns is decorative lighting.

When there are a lot of them in the room, it looks very impressive. In this case, acrylic glass or fiberglass panels are used as cladding.

- In many reputable institutions, columns are not only part of the interior, but also the main decoration of the facade. Marble and granite - this, of course, is beautiful, but it doesn’t happen that they are only faced with columns.

- If valuable types of stone are used in exterior decoration, then it will be, at a minimum, also a facing of a socle, porch, parapets. The cost of such decoration is always high, so the facades of many buildings are decorated with composite panels.

- As a rule, these are multilayer aluminum panels: modular or lengthy. Their main value lies in the fact that they are produced in any configuration and are easily cut.

With their help, columns of any shape can be lined. Radius cartridges are made using metal rolling technology. - The strength of this design ensures reliable fastening of the guide and metal bracket. Two of these details are central.

The guide has a shank forming the letter "P". The edges of the cartridge are installed in it with increased tension, and fixed by a notch located on the shank. The connection is almost imperceptible.

- But modular panels are most often made to order for a specific building. If you decide to create an unusual exterior of the columns, you can use alucobond.

From these lengthy panels, you can independently make panels, and bend them in the desired radius. - Such cladding must meet certain requirements: the integrity of the finish layer of panels; prevention of delamination of the composite during rolling, and cracking during flanging; minimum gaps at the junction of the columns.

- Alucobond is able to help in creating an original design, an excellent example of which you can see at the beginning of our article. In order for your creation to meet all of the above requirements, you will have to study a lot of materials and videos that tell you how to cut, mill and mill this material correctly.

For facing columns, especially those located inside buildings, stainless steel is often used. This is an expensive type of decoration, and is carried out, most often, when the entire interior is made in the style of techno.

A similar design of columns can be seen in car dealerships, trading floors, where wheels are exhibited, or household appliances.