Facing columns with metal: features of design and installation

Facing columns with metal is gaining great popularity in recent years. This is not surprising, since in this way you can give personality to any architectural project.

The content of the article

What are the columns made of?

The columns are decorative structures. There are a large number of materials for their construction.

What are the columns made of:

- Most often, brick, wood, foam blocks and other materials are used to build such a structure.

- The lining of the column can be any modern decoration material.

- Their shape is also diverse.

Forms of columns that can be made from the listed materials:

- Square.

- Round.

- Asymmetric.

- Rectangular

Note. The decoration of the columns with metal looks very original.

What is needed initially for finishing columns with metal

The preparatory work includes:

- Choosing the right metal (stainless steel, aluminum, titanium alloy, composite materials).

- Develop a frame design for the installation of the material.

- Calculate the required amount of metal and determine the cost of work.

- Choose the right tool for mounting the metal box.

Tip. Stainless steel is better suited for facade cladding with metal columns, because it has a higher corrosion resistance and has increased strength. For interior decoration, aluminum can be used.

- The choice of metal texture (polished, mirror, matte, perforated, with texture).

- Choice of shade cladding.

- Consider the number and location of lighting fixtures.

- Choose fasteners or type of welding equipment. To do this, you will initially need to get expert advice.

Key Aspects in Designing a Column Box

Stainless steel for column lining also good. If desired, you can give preference to another type of metal with the same qualities.

So:

- Each design of the column is calculated depending on the design parameters.

- The column is lined with metal by sheets with a thickness of 0.8 to 1.5 mm.

Note. Metal that is thicker is used only for exterior cladding.

- At the initial stage of the lining, the surface of the column is leveled and a lath of ferrous metal is made on it. Next, they assemble the main frame for the installation of the finish.

Tip. At the moment, there are ready-made decorative metal panels that are used to finish surfaces and design columns.

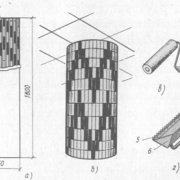

Types of columns and their sections

Columns come in several types.

Let's consider in more detail:

- Round columns. Such structures are most often used for interior and exterior decoration of balconies and other similar structures.

- Square.

- Rectangular

Tip. The metal lining of the columns depends on the shape and size of the column itself.

- Polyhedral columns. They have non-standard forms that are developed for a specific interior design.

- Vintage or roman columns. Most often they are round in shape. Facing this type of column is much more difficult.

By type of complexity, columns can be:

- Simple.A standard square reinforced concrete column on which two “deaf” U-shaped boxes from stainless steel are mounted.

- Complicated. Round reinforced concrete structure in a “deaf” metal box

- Customized. In addition to standard steel sheets, aluminum, copper and zinc materials are often used.

- Designer Based on the customer’s wishes, specialists mount perforated metal sheets with any texture and color on the basis.

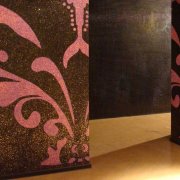

A combination of metal with glass is also possible. Lighting is laid inside the structure.

The photo shows an example of a design project for a column using metal and backlighting.

Tip. For outdoor columns, a coating that is confidently resistant to external influences (weather and climatic conditions) is better. Facing metal columns on the street is done with finished decorative elements and panels of similar material.

The advantage of columns that are lined with metal

There are some advantages to this column design method.

So:

- Aesthetics. Facing columns with stainless steel will give the old faceless designs a new look.

- Durability and durability. Stainless steel is a strong metal, not subject to corrosion and temperature influences.

- Wear resistance and durability. Corrosion-proof frame has high performance, which extends the life of the structure.

Tip. Facing the column with metal is an expensive option. The price varies from the degree of complexity of the order and ranges from $ 50-150 per m2.

- Functionality. In the space between the finish and the box lay wires, telephone cables and so on.

- Relative ease of installation and dismantling if necessary. If any part of the box is damaged, it is easily replaced with a new one. In this case, the main lining remains untouched.

Column lining sequence

Modern technologies make it possible to make metal cladding of any column. The height of the structure in some cases reaches 30 m.

The process of facing the columns:

- Initially, the suspension is done. Fastening the supporting frame made of ferrous metal, which will be attached to all further construction.

- Then the frame itself is mounted.

- Installation of facing plates is the final stage of finishing work.

For work there is an instruction according to which preparatory and finishing work is performed.

Let's consider in more detail:

- Hanging is necessary to determine the level of deviation from the vertical plane.

- If the deviation angle is insignificant, then the irregularities are corrected by installing guides and a metal box.

- With a significant deviation, there are other options for fixing defects.

- A lashing cord marks the lines along which the guides are laid. A stainless or aluminum box is mounted on the finished frame.

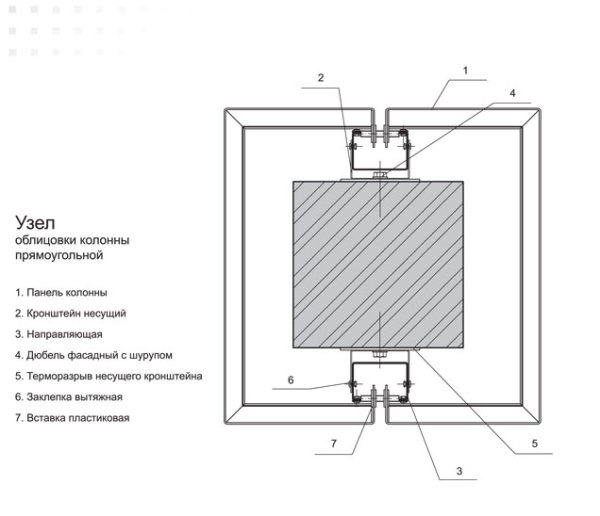

Necessary materials for the construction of the frame for cladding:

- Guides.

- Bearing bracket.

- Facade dowels.

- Thermal breaks.

- Related materials.

- The guide serves to set the direction of the seam of the frame.

- The support bracket holds the guide.

- With facade dowels, this entire structure is fixed to the column, and thermal breaks are necessary if the column is subject to temperature fluctuations.

- Thermal break is a rubber or plastic gasket, which is located between the column and the dowel head.

Tip. When you buy dowels on your own, you need to make sure that they are facade and with a screw.

Related materials:

- Rivets.

- Riveter.

- Various inserts and screws.

How to make facing columns yourself

Facing a steel column is a complex process, but with expert advice, it is possible to complete it quickly and easily.

Work:

- Initially, you need to make an accurate calculation of the frame and its components.

- Select mounting hardware.

- Order the correct bending of stainless sheets or buy decorative metal panels.

- Level guides and mount the preliminary frame

- Use rivets or blind screws to install the panels on the column.

From the tools you will need:

- Hammer drill.

- Screwdriver.

- Building level.

- Roulette.

- Plumb line.

- Another handy tool.

Column Finishing can be done by do-it-yourselfers and professionals.

More details:

- The cost of lining columns with stainless steel ranges from $ 50-60 per m2.

- Pretty expensive fun.

- The lining of the metal column is carried out only by professionals, since the main material for the installation of the finish can be soft and the lining fastening itself will have to be done not on the frame, but using self-tapping screws.

It is better to save money and lining the columns yourself. The video shows the work process.