Exterior wall paneling: choose the best

Wooden lining is widely used for finishing both internal walls and for facing facades. The term “lining” has taken root on this facing material in the construction market not so long ago.

In this way, the walls of the cars were sheathed so that there were no cracks. Nowadays, the lining is made of natural wood or PVC (polyvinyl chloride).

The content of the article

Lining from a natural tree

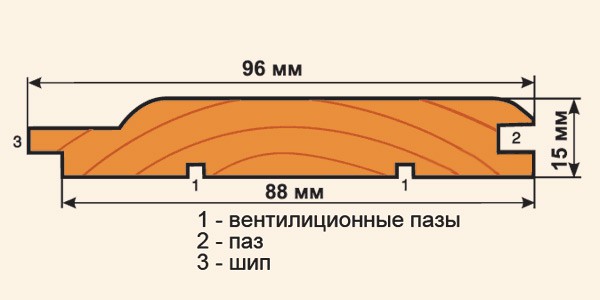

Wooden lining is a dried and planed board on all sides with a specific profile. This board has the entire length, on one side there is a groove, and on the other hand, a spike.

During installation, the spike of one board enters the groove of the other and as a result, a monolithic wall without gaps and gaps is obtained. There is still such a thing as euro lining.

This lining differs from ordinary lining in the form of a profile, as well as in overall dimensions. Euro lining has deeper grooves and correspondingly longer spikes.

The main difference between eurolining is the presence of longitudinal recesses that perform a ventilation role.

Domestic manufacturers produce lining of the following sizes:

- the width of the board should not be higher than 150 mm;

- the length of the board should be no more than 6000 mm;

- board thickness can vary from 12 to 25 mm;

Euro lining standards are much stricter:

- width should be 80 mm, 100 mm, 110 mm or 120 mm;

- the length of the board varies widely from 500 mm to 6000 mm;

- board thickness should be 13 mm, 16 mm or 19 mm.

As raw materials for the manufacture of facade cladding, both deciduous trees and conifers are used:

- Pine;

- spruce;

- aspen;

- larch;

- ash;

The most common wood for the production of facade clapboard is spruce. The resins and essential oils that make up this tree have an amazing healing aroma, and antimicrobial (antiseptic) properties have been known since ancient times.

By quality, the lining is divided into 4 classes:

- Class Extra - such a material has no flaws, its surface is perfectly smooth.

- Class A - allows no more than one knot on an area of 1.5 square meters. meter. There may be slight bumps on the surface.

- Class B - allows for the presence of four knots on an area of 1.5 square meters. meters, two tar pockets and two dark spots.

- Class C - allows a larger number of captive knots with a diameter of up to 25 mm, one dark spot with an area of up to 25 cm². Resin pockets no more than four pieces.

The choice of wooden lining should be approached very carefully.

To choose the right material, you must follow these tips:

- Be sure to ask the seller what kind of wood it is made from. For facade decoration it is better to use a lining made of coniferous trees.

A large number of resins will protect the wood product from wet deformation. - If funds allow, then pick up the lining class Extra. Its quality will allow revetment of the facade to everyone for a feast for the eyes and it will serve much longer than the lining of lower grades.

- Ask your consultant how the lining was dried. The strength and durability of the material will depend on the quality of the dried wood.

Wood, which was dried in special drying chambers, although it will cost more, will also serve you for many years. - The store can offer you two types of facing material - a standard lining or euro.Euro lining applies more stringent production conditions.

And it will cost more. Although some characteristics practically do not differ from the characteristics of a standard lining. - Before going to the store, measure all the walls that you are going to revet and calculate the approximate amount of the necessary material. We advise you to buy material with some margin.

If you come to the store with a drawing of the house, then the sales assistant will help you choose the hardware parts:

- facing strip;

- starting bar;

- finish bar;

- hinged level;

- connecting strip.

From the wide range of colors, choose the one that meets your ideas.

Exterior finish of a wooden house with clapboard

Finishing the facade of a wooden house It is necessary to produce in order to protect the load-bearing walls of the house from adverse weather conditions. One of the methods of facade cladding is lining it with a wooden lining.

Exterior decoration of the facade with a wooden clapboard is a simple job and it can easily be done independently, with one assistant with you.

You will need such tools and materials:

- drill with punch function;

- screwdriver;

- jigsaw;

- roulette;

- hammer;

- pencil;

- level;

- dowels 6x80 mm;

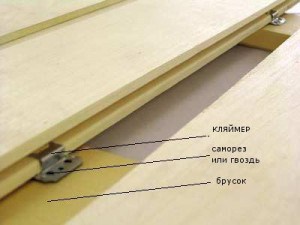

- kleimers;

- nails of 20 mm;

- wooden beam 20x40 mm;

- wooden lining.

Since there are no perfectly even walls, we will fasten the lining to the crate. In addition, you can additionally insulate the house if you put foam sheets between the bars of the battens on the thickness of the bars.

So:

- Lathing bars should be placed vertically at a distance of 50 cm from each other. They are attached to the wall with dowels.

The gaps between the bar and the wall are removed using wooden linings.

Before starting the decoration, the lining should be impregnated with an antiseptic on the inside so that pests do not wound up and spoil the lining.

- We begin to mount the lining from below. We lay the first board with the spike up, so that moisture does not accumulate in the connection.

We expose it in level, strictly horizontally. We fix the lower end of the board with screws to the crate.

Subsequently, they will be closed with the initial bar. We fix the upper end of the board with clamps. - We put the next board on the spike of the first board. The connection should be tight.

In order not to damage the junction, it is necessary to knock the lining with a short piece of lining putting it on a spike.

- Thus, we collect the lining to the very top. Periodically, after 2-3 rows, check the horizontal positioning by level.

- The external and internal corners are closed with the corresponding slats for glue “liquid nails”.

- The start and finish strips are also fixed with glue.

- We trim door and window openings with decorative boards.

Since wood lining is afraid of moisture, it should be varnished in two layers. The first layer is applied with varnish diluted with a solvent so that the varnish soaks the wood as deep as possible.

Apply the second coat with undiluted varnish. The varnish will protect your lining and give it a more attractive look.

Facing the facade with a wooden lining

We finish the facade with wooden panels in the same sequence as wooden house decoration.

We expose the lining with antiseptic impregnation. We fasten the crate with dowels.

We begin installation from below. We set the first board according to the level, we apply two layers of protective varnish.

Facade decoration with plastic lining

The most popular facade decoration is a plastic lining.

It is made from hard polyvinyl chloride (PVC). Mainly, PVC lining is used for exterior cladding of the facade.

The advantages of plastic lining are:

- absolutely does not absorb moisture;

- durability;

- resistance to ultraviolet rays, does not fade in the sun;

- easy to process;

- high frost resistance;

- fire safety;

- resistance to adverse weather conditions;

- high heat and sound insulation;

- ease of installation;

- rich color palette.

The installation of a plastic lining practically does not differ from the installation of a wooden lining; the same tools and materials will be required for work. Instead of wooden lining, buy plastic.

So:

- Mount the crate. If you plan to insulate the facade, then select the thickness of the beam according to the thickness of the insulation.

- The distance between the bars of the crate should be 50 cm, so that the foam plates can not be cut.

- We begin to mount the lining from the lowest strip with the groove down so that moisture and dirt do not collect there. Be sure to set it level strictly horizontally.

- We fix the upper edge of the strip with the clamps.

- We put the next strip on the spike of the first strip, and the upper edge is also fixed with kleimers.

- Thus, we install to the ceiling.

- We adjust the upper strip in width and fix it with screws.

- We close corners with special corners on glue for plastic like Dragon.

- The gaps at the top and bottom are covered with glue strips.

The plastic lining for the decoration of facades also has disadvantages:

- as an artificial material, it releases phenols that are harmful to health;

- this is a fragile material, it is impossible to hang a load of more than 1.5 kg on it;

- it can easily be damaged even with a slight blow.

The cost of lining the exterior walls with a plastic lining will be slightly lower so as you do not have to grind, tint and varnish it.